Butyl tape with aluminium lamination

Butyl sealing tape with aluminium lamination

SEALTPE-BUTYL-EX-ALULAMINATION-45MMX20M

Register now and access more than 125,000 products

Good UV, weathering and water resistance

- The butyl tape can also be used outdoors and withstands rain and any other weather effects (not suitable for use under water).

- Non-corrosive

Excellent adhesion to absorbent and non-absorbent substrates

Can be used on all substrates present in the construction sector, e.g. steel, aluminium, glass, plastic, wood, concrete, masonry, bitumen etc.

Butyl tapes are self-bonding

The tape is fully functional immediately after application and complies with all required properties.

Impermeable to vapour diffusion

The butyl tape enables water-tight sealing and prevents moisture from penetrating the building.

- No bimetal effect

- Compatible with bitumen

- Sound insulating

- Easy to apply

- Odourless

- Suitable for contact with food

- Solvent free and bitumen free

- Complies with IVD technical data sheets no. 5, 19-1, 19-2, 25, 29, 31, 35

- Compatible with bitumen in accordance with DIN EN 1548

ISEGA:

- For sealing piping systems in which dry food is transported

- Clearance certificate no.: 65015 U 25

Complies with VOC requirements according to:

- EMICODE EC 1 Plus

- AgBB scheme

- French VOC Class A+ and "KMR ordinance"

- Screwing in/penetrating the butyl tape must be avoided

- Butyl cannot be secured mechanically!

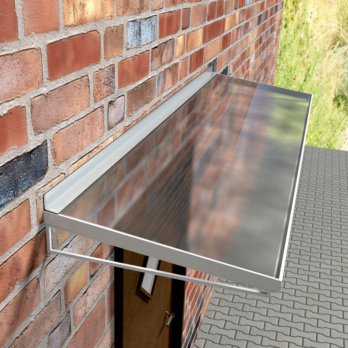

The aluminium sealing tape is perfect for overlapping in order to seal the frame opposite the areas adjoining the roof recess

The aluminium sealing tape is perfect for overlapping in order to seal the frame opposite the areas adjoining the roof recess

Datasheets(X)

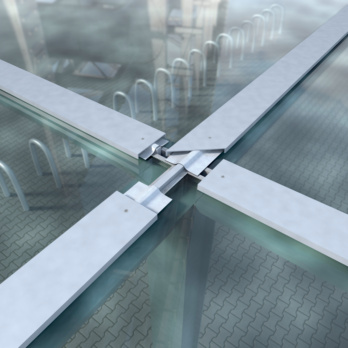

For covering seals of construction and connection joints in areas of industry and construction, concrete and concrete finished parts construction. Typical applications include sealing domed roof lights, window frames, slanted-roof glass structures (with press-on profile only), greenhouses, conservatories and other butt joints made from glass, plastic and metal. Also suitable for sealing roof penetrations, rain gutter connections, connections between projecting roofs and masonry as well as piping systems in which dry food is transported.

The surfaces to be sealed must be dry, capable of bearing load and free from grease and dust. The application temperature should not be below +10°C. Absorbent and porous surfaces must be pre-treated with Würth butyl/bitumen primer (art. no. 0892875).

To obtain good initial adhesion to the surface, the tape should be pressed onto the surface and smoothed using a press-on roller (art. no. 0693011756). Folds and creases should be avoided.

Butyl has a "cold flow" tendency (flow characteristic of the tape). Therefore, the tape should always be fitted with a press-on profile to prevent the seal from slipping as a result of, for example, the weight of snow or backed-up water. However, using excessive contact pressure on the profile will cause the sealing compound to be "pushed out". Also, never compress the butyl tape to the zero point (use the supplied disc as a spacer)!

The adhesive surface of the sealing tape must be at least 1/3 (per contact surface) of the tape width when gluing over joints. Overhead adhesion tasks are not permitted without additional mechanical fixings. When sealing glass retainer profiles, the rubber profile must not lie on the sealing tape. The width of the butyl tape must be selected such that the tape is located between the rubber profiles.

Chemical basis | Butyl natural rubber |

Design | With aluminium lamination |

Backing material | Aluminium composite foil |

Colour | Black |

Length | 20 m |

Width | 45 mm |

Overall thickness | 1.5 mm |

Thickness of butyl compound | 1.4 mm |

Backing material thickness | 0.04 mm |

Building material class/conditions | B2 - Normally inflammable / in accordance with DIN 4102 |

Min./max. processing temperature | 5 to 30 °C |

Min./max. temperature resistance | -40 to 90 °C |

Resistance against | Water, Weather |

Ultraviolet resistance | Yes |

Shelf life from production/conditions | Unlimited / dry, lying and dust-free storage area, 20°C and 50% humidity |