Fixanchor W-FA/S

Fixanchor W-FA steel zinc plated small washer

ANC-(W-FA/S)-(A2K)-5-M6X40

Art.-no. 5932006040

EAN 4047376681941

Price for selected packaging unit

Exclusively for trade customers

Register now and access more than 125,000 products

Stud anchor for standard applications in uncracked concrete. Zinc-plated steel

- Very flexible application thanks to 3 effective anchorage depths

- Small axis and edge distances

- Time-saving in-place installation

Proof of Performance

- European Technical Assessment ETA-02/0001 for individual attachment, option 7, uncracked concrete: Static or quasi-static exposure (M6-M20)

- Fire resistance: F30, F60, F90 and F120; exposure to fire according to DIN 4102-2:1977-09 (uniform temperature curve)

Application area

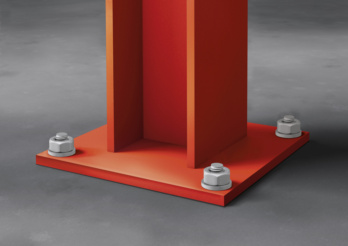

Heavy steel structures

Heavy steel structures

Fence systems

Fence systems

Post support bracket

Post support bracket

Heavy steel structures

Heavy steel structures

Fence systems

Fence systems

Post support bracket

Post support bracket

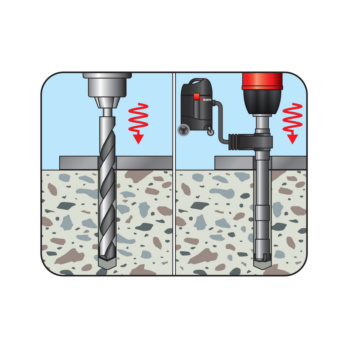

Create the drill hole

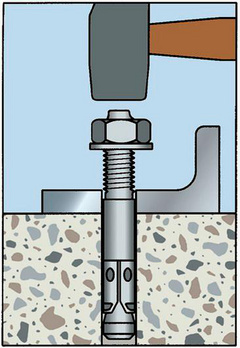

Knock in anchor with mason's mallet or machine setting tool

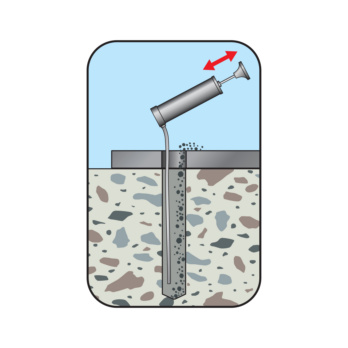

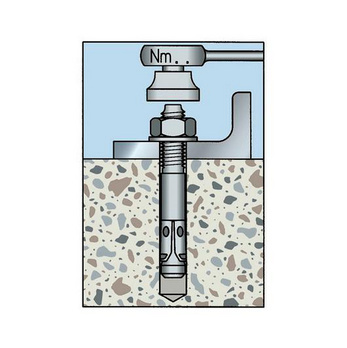

Apply torque

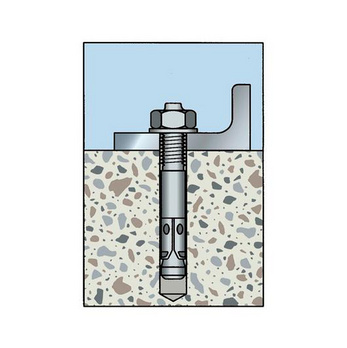

Set anchor in place

Product information

Datasheets(X)

CAD data (available after login)

Application area

- Individual or multiple attachment approved in normal weight concrete C20/25 to C50/60 (uncracked concrete only)

- For use in concrete < C20/25 and pressure-resistant natural stone without approval

- Suitable for anchoring medium to heavy loads in concrete: Mounting of e.g. metal structures, metal profiles, brackets, base plates, cable conduits, pipes, wooden structures, beams, purlins, fences etc.

- The W-FA/S galvanised steel is suitable for use in dry indoor areas

Metric anchor diameter | M6 |

Anchor length (l) | 40 mm |

Material | Steel |

Surface | Zinc plated |

Attachment height (t fix) | 5 mm |

Drill hole depth (h 1) | 45 mm |

Drill hole depth reduced (h 1, red) | 45 mm |

Effective anchoring depth (h ef) | 27 mm |

Embedding depth (h nom) | 49 mm |

Embedding depth (h nom,red) | 39 mm |

Width across flats | 10 mm |

Nominal drill-bit diameter (d 0) | 6 mm |

Torque during anchoring (T inst) | 8 Nm |

Through-hole in the component to be connected (d f) | 7 mm |

Thread length (L th) | 16 mm |

Approval | No |

| Performance data | ||||||||||||||

| Anchor diameter [mm] | M6 | M8 | M10 | M12 | M16 | M20 | ||||||||

| Standard effective anchorage depth/reduced effective anchorage depth | hef/hef red [mm] | 40 | 30 | 44 | 35 | 48 | 42 | 65 | 50 | 82 | 64 | 100 | 78 | |

| Admissible centric tension load1) on an individual anchor without the influence of the edge distance | Compressive zone (uncracked concrete) C20/252), s ≥ 3 hef c ≥ 1.5 hef) | Nadm [kN] = C20/252) | 4,1 | 2,9 | 5,7 | 5,0 | 7,6 | 6,5 | 12,6 | 8,5 | 17,8 | 12,3 | 24 | 16,5 |

| Permissible shear load1) on an individual anchor without the influence of the edge distance | Compressive zone (uncracked concrete) C20/252), c ≥ 10 hef) | Vadm [kN] = C20/252) | 2,9 | 2,9 | 6,3 | 5,0 | 8,0 | 6,5 | 14,3 | 8,5 | 23,6 | 23,6 | 37,1 | 33,1 |

| Permissible bending moment | Madm [Nm] | 5,1 | 5,1 | 13,1 | 13,1 | 25,7 | 25,7 | 44,6 | 44,6 | 99,9 | 99,9 | 195 | 195 | |

| Fire resistance rating (W-FA/S) | F30 [kN] | 0,9 | - | 1,4 | - | 2,2 | - | 3,2 | - | 6,0 | - | 10,0 | - | |

| F60 [kN] | 0,5 | - | 0,8 | - | 1,2 | - | 1,8 | - | 3,4 | - | 5,25 | - | ||

| F90 [kN] | 0,3 | - | 0,5 | - | 0,8 | - | 1,2 | - | 2,2 | - | 3,6 | - | ||

| F120 [kN] | 0,25 | - | 0,4 | - | 0,6 | - | 0,9 | - | 1,7 | - | 2,75 | - | ||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. Please refer to the European Technical Approval Guidelines (ETAG), Appendix C, for information on combining tensile and shear loads, the influence of the edge distance and groups of anchors. 2) The concrete has normal reinforcement. Higher values are possible for higher concrete compressive strengths. | ||||||||||||||

| Characteristic values | |||||||||||||

| Embedment depth | hnom/hnom,red [mm] | 49 | 39 | 56 | 47 | 62 | 56 | 82 | 67 | 102 | 84 | 121 | 99 |

| Nominal drill ∅ | d0 [mm] | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 16 | 16 | 20 | 20 |

| ∅ of cutting edges | dcut ≤ [mm] | 6,4 | 6,4 | 8,45 | 8,45 | 10,45 | 10,45 | 12,5 | 12,5 | 16,5 | 16,5 | 20,55 | 20,55 |

| Drill hole depth | h1/h1,red ≥ [mm] | 55 | 45 | 65 | 55 | 70 | 65 | 90 | 75 | 110 | 95 | 130 | 110 |

| Through hole in the component being connected | df ≤ [mm] | 7 | 7 | 9 | 9 | 12 | 12 | 14 | 14 | 18 | 18 | 22 | 22 |

| Torque when anchoring (W-FA/S, zinc-plated steel) | Tinst = [Nm] | 8 | 8 | 15 | 15 | 30 | 30 | 50 | 50 | 100 | 100 | 200 | 200 |

| Torque when anchoring (W-FA/F, hot-dip galvanised steel) | Tinst = [Nm] | - | - | 15 | 15 | 30 | 30 | 40 | 40 | 90 | 90 | 120 | 120 |

| Individual fixing point | |||||||||||||

| Uncracked concrete, option 7 (ETA-02/0001 - zinc-plated steel and hot-dip galvanised steel) | |||||||||||||

| Anchor diameter [mm] | M6 | M8 | M10 | M12 | M16 | M20 | |||||||

| Standard effective anchorage depth/reduced effective anchorage depth | hef/hef,red [mm] | 40 | 30 | 44 | 35 | 48 | 42 | 65 | 50 | 82 | 64 | 100 | 78 |

| Axis distance | scr,N [mm] | 120 | 90 | 132 | 105 | 144 | 126 | 195 | 150 | 246 | 192 | 300 | 234 |

| Edge distance | ccr,N [mm] | 60 | 45 | 66 | 53 | 72 | 63 | 98 | 75 | 123 | 96 | 150 | 117 |

| Minimum axis distance | smin [mm] | 35 | 35 | 40 | 40 | 55 | 55 | 75 | 100 | 90 | 100 | 105 | 140 |

| Minimum edge distance | cmin [mm] | 40 | 40 | 45 | 45 | 65 | 65 | 90 | 100 | 105 | 100 | 125 | 140 |

| Minimum member thickness | hmin [mm] | 100 | 80 | 100 | 80 | 100 | 100 | 130 | 100 | 170 | 130 | 200 | 160 |