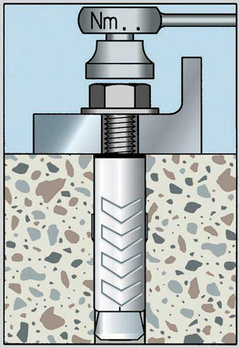

Heavy-duty anchor W-TM type O with eyelet

Heavy-duty anchor W-TM type O steel zinc plated

ANC-(W-TM/S-O)-(A2K)-M8X51

Art.-no. 0904901866

EAN 4045989060771

Price for selected packaging unit

Exclusively for trade customers

Register now and access more than 125,000 products

For uncracked concrete, zinc-plated steel

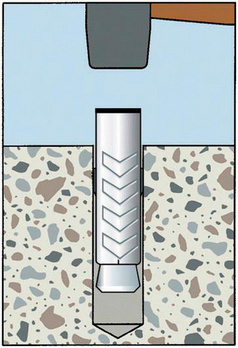

- Minimal effort required to insert anchor

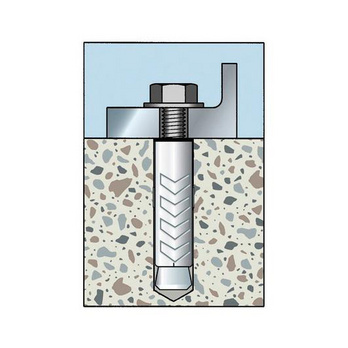

- Immediate load-bearing capacity — no waiting

- No setting tools required

- Can be set flush with surface

- Triple expansion sleeve to ensure even expansion and load distribution

- Applying the specified torque during the anchoring process ensures secure installation

- Load-controlled/torque-controlled expanding galvanised steel anchor in sizes M6–M12

- Cotter-pin installation

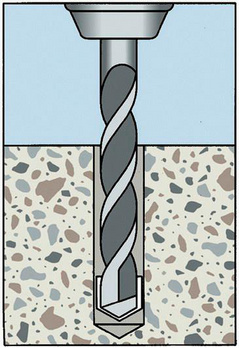

Create the drill hole

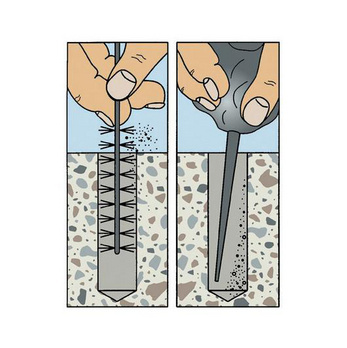

Clean the drill hole

Knock in anchor until flush

Mount component

Apply torque

Product information

Datasheets(X)

Application area

- Can be used for medium to heavy loads

- Suitable for fastening: Transfer lines on the ground requiring installation flush with the surface; steel structures, metal profiles, brackets, base plates, cable conduits, piping, mounting rails etc.

- Can be used in concrete

- The anchor may be used for anchorages with predominantly static loads or quasi-static loads

- Individual fixing point: Anchorage in uncracked concrete

- May only be used in dry indoor conditions

| |

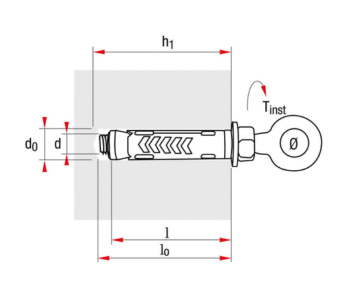

Anchor diameter | 8 mm |

Anchor length (l) | 51 mm |

Nominal drill-bit diameter (d 0) | 12 mm |

Drill hole depth (h 1) | 61 mm |

Effective anchoring depth (h ef) | 44.5 mm |

Material | Steel |

Surface | Zinc plated |

Torque during anchoring (T inst) | 12 Nm |

Through-hole in the component to be connected (d f) | 9 mm |

| Performance data | ||||||

| Anchor diameter [mm] | M6 | M8 | M10 | M12 | ||

| Recommended load of an individual anchor without influence of the edge distance type O | Compressive zone (uncracked concrete C20/252)), s ≥ 3 hef, c ≥ 1.5 hef | Nrec [kN] = C20/252) | 1,4 | 2,4 | 3,6 | 6,0 |

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of YF = 1.4 have been taken into account. Please refer to the European Technical Approval Guidelines (ETAG), Appendix C, for information on combining tensile and transverse loads, edge influence and groups of anchors. 2)The concrete has normal reinforcement. Higher values are possible for higher concrete compressive strengths. 3) Compliant with approval if screws and threaded rods with acceptance test certificate 3.1 in accordance with EN 10204:2004 are proven to be the required material and to possess the mechanical properties stipulated in ETA-10/0255. 4) Type S: If a lower fixture thickness is required, make a deeper drill hole accordingly. | ||||||

| Characteristic values | |||||

| Minimum member thickness | hmin ≥ [mm] | 135 | 135 | 140 | 160 |

| Minimum spacing | smin ≥ [mm] | 65 | 90 | 135 | 165 |

| Minimum edge distance | cmin ≥ [mm] | 45 | 70 | 85 | 115 |

| Spacing | scr,N [mm] | 119 | 134 | 155 | 189 |

| Edge distance | ccr,N [mm] | 60 | 67 | 78 | 95 |

| Effective anchorage depth | hef [mm] | 39,5 | 44,5 | 51,5 | 63,0 |

| Nominal drill diameter | d0 [mm] | 10 | 12 | 14 | 18 |

| Diameter of cutting edges | dcut ≤ [mm] | 10,45 | 12,5 | 14,5 | 18,5 |

| Drill hole depth4) | h1 ≥ [mm] | 55 | 61 | 70 | 85 |

| Through hole in the component being connected | df ≤ [mm] | 7 | 9 | 12 | 14 |

| Torque during anchoring (type A + type S) | Tinst [Nm] | 10 | 25 | 40 | 75 |

| Torque during anchoring (type O + type H) | Tinst [Nm] | 5 | 12 | 20 | 35 |