- Type M (medium): up to and including screw connections of strength class 8.8 with normal head contact

- Protection type: Screw retainer

- Friction locking thanks to spring force

- Mechanical interlock thanks to specific surface stamping

- Protects the counter surface from damage (washer does not turn during installation)

- Minimal tightening torque distribution

Product information

Datasheets(X)

Application area

Machine and system construction, drive technology, conveyor technology, commercial vehicles, construction machines, vehicle construction, agricultural technology, the food industry etc.

| |

Suitable for screw thread | M24 |

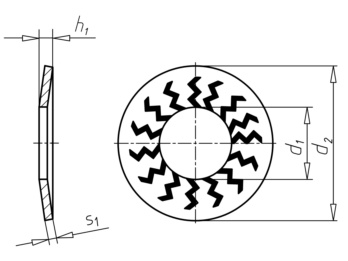

Internal diameter (d1) | 25 mm |

Outer diameter (d2) | 50 mm |

Height (h1) | 5.15 mm |

Thickness (s1) | 3.5 mm |

Material | Spring steel |

Min./max. Vickers hardness, HV | 420-510 HV |

Surface | Flake zinc silver |

RoHS-compliant | Yes |

Corrosion protection period | 720 h |

Form | M |

Locking device operating principle | Serrated lock washer |

Locking function | Embedding locking device |

Comparison of locking disc spring washers and lock washers | |

| Locking disc spring washer | Lock washer with no DIN standard |

| + Twice as secure: spring-secured friction fit and positive locking + Minimal tightening torque distribution + Application range up to approx. 350°C + Reusable + Protection of the counter surface; no turning | Without a DIN standard, lock washers become a safety risk! - Very high tightening torque distribution - Only suitable for locking screws 5.8 - In the worst case scenario, lock washers can wear through surfaces and thereby promote a drop in the preload force. - No protection against unscrewing - Lock washers are not reusable - Lock washers tend to expand (risk of breakage) - They turn during tightening and loosening -> This damages the surface/counter surface |