Milling cutter SC SPEEDCUT Aluminium XL HB, triple blade

End mill SC Alu WN-XL Z3 3xD/2xD W 34-38° HB

CTR-SC-SP-WN-AL-EL-HB-D4,0MM

Art.-no.

5443300992

EAN 4055375924044

Price for selected packaging unit

Exclusively for trade customers

Register now and access more than 125,000 products

Ideal for working with aluminium materials (cast and wrought aluminium alloys). Core taper for maximum stability, optimal chip flow with optimised production grinding process, producing extremely smooth surfaces. Maximum chipping rates and optimal surface quality with unique cutting geometry.

Product information

Datasheets(X)

| |

Product code | 7920 |

Material to be processed | Copper, Brass, Aluminium, Plastic |

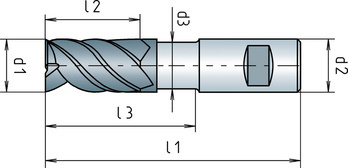

Diameter (d1) | 4 mm |

Shank diameter (d2) | 6 mm |

Clearance diameter (d3) | 3.8 mm |

Standards | CS |

Construction length | Extra long |

Shank style | Cylindrical DIN 6535-HB |

Cutting material | SC |

Surface | Plain |

Coolant supply | External |

Twist angle | 34-38° |

Length (l1) | 60 mm |

Cutting edge length (l2) | 11 mm |

Clearance length (l3) | 21 mm |

Number of cutting edges (Z) | 3 PCS |

Corner chamfer | 0.06 mm |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | Copper, Brass, Aluminium, Plastics |