Powerbond bodywork adhesive

Bodywork adhesive Powerbond

BDYWRKADH-2C-POWERBOND-CARTRIDGE-225ML

Register now and access more than 125,000 products

High-strength epoxy resin adhesive

- The repair restores the original strength and stiffness

- Fewer spot welds

- Meets the requirements of automotive manufacturers

Glass particle technology

Even if too much pressure is exerted, an adhesive layer thickness of 0.25 mm is guaranteed

Excellent stability

The adhesive will not run on vertical surfaces (thixotropic)

Excellent corrosion protection

- The original degree of rust resistance is maintained

- Corrosion is prevented from occurring at spot welds

Weldable

Can be sanded and painted over

Silicone- and VOC-free

Not suitable for load-bearing bodywork parts (e.g. A-pillars, longitudinal chassis beams etc.). When replacing parts, do not glue on visible surfaces, as "shadow lines" may appear. The product must be stored in a frost-free location. For cordless or pneumatic guns, the lowest setting/feed should be used to prevent the cartridge from deforming.

Datasheets(X)

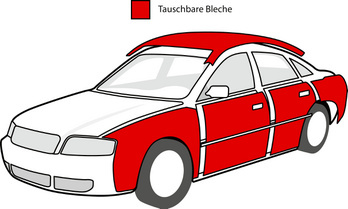

Structural adhesive for steel, aluminium, stainless steel and glass fibre-reinforced plastics (GFRP, CFRP). For bonding bodywork parts such as mudguards, side walls, wheel arches, roof panels and door panels.

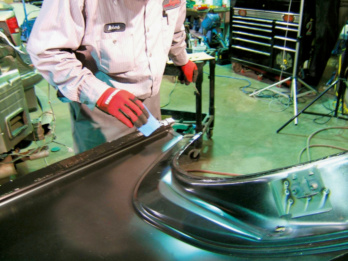

The substrate must be capable of bearing loads and must be clean, dry and free from grease and rust. Old adhesive residues must also be removed. Observe the processing instructions. For more information, refer to the technical data sheet.

Container | Double cartridge |

Chemical basis | Epoxy resin |

Colour | Black |

Density | 1.1 g/cm³ |

Smell/fragrance | Characteristic |

Min. tensile strength | 30 N/mm² |

Min. combined tension and shear resistance | 28 N/mm² |

Conditions for combined tension and shear resistance | after four hours, 23°C, EN 1465 |

Conditions for tensile strength | at 23°C, in accordance with ASTM D-638 |

Shore D hardness | 80 |

Conditions for Shore hardness | in accordance with DIN 53505 |

Working life | 60 min |

Conditions for working life | at 23°C |

Curing time | 4 h |

Min./max. temperature resistance | -30 to +120 °C |

Min./max. processing temperature | 15 to 25 °C |

Max. short-term temperature resistance | 190 °C |

Max. final strength | 24 h |

Conditions for final strength | at 23°C |

Resistance against | Petrol, Diesel, Cooling liquid, Engine and gear oils |

VOC-free | Yes |

Silicone-free | Yes |

Shelf life from production | 24 Month |

Additional articles | Acetone cleaner, art. 0893460; Quattro rust stop, art. 08932141; pneumatic axial grinder, art. 07032310; Flexi-Disc, art. 0578705 …; nylon fleece disc, art. 067322 50/75; mini fleece disc, art. 0673205.../207...; locking pliers, art. 071409... |

Contents | 225 ml |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!