Sealing tape VKP® Trio SF

Sealing tape VKP Trio SF

SEALTPE-RAL-VKP-TRIO-SF-40/7-15MM-8M

Art.-no. 0875364007

EAN 4046777027259

Register now and access more than 125,000 products

Tested sealing properties over 600 Pa, complies with BG1 requirements in accordance with DIN 18542

Tested air tightness properties (a < 0.1) meet BGR requirements in accordance with DIN 18542

Tested and assured sealing against driving rain

Time-saving application

Resistant to driving rain, heat-insulating and air-tight in a single product

Outwardly permeable to water vapour

The surface waterproofing on one side achieves the required vapour diffusion property of "tighter sealing on the inside than the outside".

Can be installed in any weather

The product provides completely secure sealing in virtually any kind of weather.

No chemical reactions with other materials

The tape is resistant to driving rain, but must also be sealed with butyl tape with laminated foil for standing water (e.g. horizontal and above) or water pressing on the seal, if the joint is not immediately covered following mounting. A second level leading water away (tub-shaped sealing film) must be created in the lower connection area, so that the water is diverted away to the outside in a controlled manner. The expansion speed of VKP Trio SF depends on the temperature. In high temperatures, store the tape in a cool location; in low temperatures, store in a warm location.

Datasheets(X)

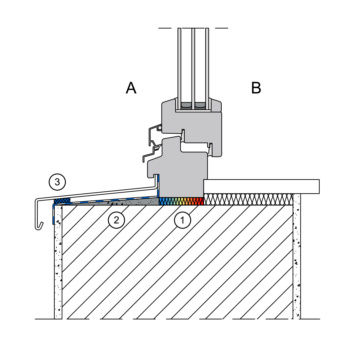

- For use when installing construction elements with a narrow joint depth. For instance, when fitting elements that only partially sit in the reveal, such as when combined with thermal insulation composite systems or front-mounted façades.

- VKP Trio SF is waterproofed on the inside, which is dyed grey. In the joint, this waterproofing guarantees that the vapour diffusion gradient from inside to outside required by the RAL-Gütegemeinschaft für Fenster und Haustüren (RAL Quality Association for Windows and Doors) is achieved.

1. Preparation:

- Roughly clean the surfaces of soiling.

- Cut off approximately 2 cm from the beginning and end of the tape.

- Take the additional length of approx. 2 cm/m into account when cutting the tape to length.

2. Installation on window:

- Remove the protective film from the self-adhesive strip and adhere the tape to the window profile.

- Make sure the positioning is correct internally and externally (grey colour on the inside).

3. Appearance in the corner area:

- The tape will meet bluntly in the corners; compress in longitudinal direction.

- Leaks must always be avoided.

| |

Colour | Anthracite |

Backing material | PUR foam |

Chemical basis | Impregnated polyurethane foam |

Width | 40 mm |

Thickness | 7 mm |

Min./max. joint width for watertightness in driving rain | 7-15 mm |

Length of roll | 8 m |

Water-vapour diffusion resistance (description) | Inside more impermeable than outside |

Min./max. processing temperature | 5 to 23 °C |

Min./max. temperature resistance | -30 to 80 °C |

Min. resistance against driving rain (pressure)/conditions | 600 Pa / in accordance with DIN 18542-BG1 |

Building material class/conditions | B2 - Normally inflammable / in accordance with DIN 4102 |

Ultraviolet resistance | Yes, when compressed to be resistant to driving rain, outdoor weathering |

Shelf life from production/conditions | 24 Month / at 1°C to 20°C |