Shell end mill HSCo DIN 841 type H

Shell end mill HSCo DIN 841 Z10-16 20° type H

SHELLENDMILL-DIN841-HSCO-H-D40,0X20,0MM

Art.-no. 5443601083

EAN 4055375880586

Price for selected packaging unit

Exclusively for trade customers

Register now and access more than 125,000 products

For hard, short-chipping materials such as grey cast iron, brass, bronze, alloyed tool steels.

Product information

Datasheets(X)

| |

Product code | 3054 |

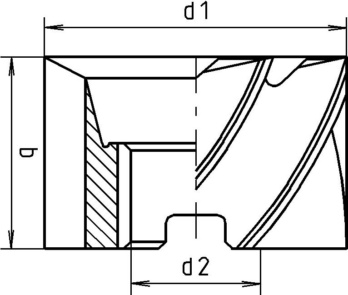

Diameter (d1 (js 16)) | 40 mm |

Height (b (k16)) | 20 mm |

Bore diameter (d2 (H7)) | 16 mm |

Number of cutting edges (Z) | 10 PCS |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium |

Standards | DIN 841 |

Cutting material | HSCo |

Surface | Plain |

Twist angle | 20° |

Tool holding device | With crosswise and longitudinal slot DIN 138 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys |

| Cutting values for roughing contour | |||||

| For dia. 30 to dia. 90 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 30 to dia. 31.9 | Dia. 32 to dia. 90 | ||||

| General structural steels | < 500 N/mm² | E | 37 | 0,078 | 0,100 |

| 500-850 N/mm² | E | 30 | 0,069 | 0,088 | |

| Carbon steels | < 850 N/mm² | E | 34 | 0,069 | 0,088 |

| 850-1000 N/mm² | E | 26 | 0,069 | 0,088 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 33 | 0,069 | 0,088 |

| 700-850 N/mm² | E | 30 | 0,069 | 0,088 | |

| 850-1000 N/mm² | E | 24 | 0,069 | 0,088 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 22 | 0,069 | 0,088 |

| 1000-1200 N/mm² | E | 18 | 0,078 | 0,100 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 30 | 0,069 | 0,088 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 22 | 0,069 | 0,088 |

| 1000-1200 N/mm² | E | 18 | 0,078 | 0,100 | |

| Nitriding steels | < 1000 N/mm² | E | 22 | 0,069 | 0,088 |

| 1000-1200 N/mm² | E | 18 | 0,078 | 0,100 | |

| Tool steels | < 850 N/mm² | E | 26 | 0,069 | 0,088 |

| 850-1100 N/mm² | E | 16 | 0,078 | 0,100 | |

| 1100-1400 N/mm² | E | 9 | 0,078 | 0,100 | |

| High-speed steels | 850-1200 N/mm² | E | 8 | 0,078 | 0,100 |

| Wear-resistant constructional steel | 1350 N/mm² | E | 9 | 0,078 | 0,100 |

| Spring steels | < 1200 N/mm² | E | 8 | 0,078 | 0,100 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 24 | 0,069 | 0,088 |

| Stainless steels, austenitic | < 700 N/mm² | E | 18 | 0,069 | 0,088 |

| < 850 N/mm² | E | 12 | 0,069 | 0,088 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 9 | 0,078 | 0,100 |

| Cast iron | < 180 HB | - | 34 | 0,069 | 0,088 |

| > 180 HB | - | 30 | 0,069 | 0,088 | |

| Nodular graphite, malleable iron | > 180 HB | - | 26 | 0,069 | 0,088 |

| > 260 HB | E | 18 | 0,069 | 0,088 | |

| Titanium, titanium alloys | < 850 N/mm² | E | 9 | 0,078 | 0,100 |

| Legend | ||

| E = emulsion | ae = 0.1xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1.5xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||

| Cutting values for finishing contour | |||||

| For dia. 30 to dia. 90 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 30 to dia. 31.9 | Dia. 32 to dia. 90 | ||||

| General structural steels | < 500 N/mm² | E | 45 | 0,057 | 0,080 |

| 500-850 N/mm² | E | 38 | 0,050 | 0,069 | |

| Carbon steels | < 850 N/mm² | E | 38 | 0,035 | 0,048 |

| 850-1000 N/mm² | E | 30 | 0,035 | 0,048 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 38 | 0,035 | 0,048 |

| 700-850 N/mm² | E | 38 | 0,035 | 0,048 | |

| 850-1000 N/mm² | E | 30 | 0,035 | 0,048 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 30 | 0,035 | 0,048 |

| 1000-1200 N/mm² | E | 25 | 0,040 | 0,054 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 38 | 0,035 | 0,048 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 30 | 0,035 | 0,048 |

| 1000-1200 N/mm² | E | 25 | 0,040 | 0,054 | |

| Nitriding steels | < 1000 N/mm² | E | 30 | 0,035 | 0,048 |

| 1000-1200 N/mm² | E | 25 | 0,040 | 0,054 | |

| Tool steels | < 850 N/mm² | E | 38 | 0,035 | 0,048 |

| 850-1100 N/mm² | E | 25 | 0,040 | 0,054 | |

| 1100-1400 N/mm² | E | 20 | 0,040 | 0,054 | |

| High-speed steels | 850-1200 N/mm² | E | 20 | 0,048 | 0,064 |

| Wear-resistant constructional steel | 1350 N/mm² | E | 15 | 0,040 | 0,054 |

| Spring steels | < 1200 N/mm² | E | 15 | 0,040 | 0,054 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 38 | 0,035 | 0,048 |

| Stainless steels, austenitic | < 700 N/mm² | E | 38 | 0,035 | 0,048 |

| < 850 N/mm² | E | 30 | 0,035 | 0,048 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 25 | 0,040 | 0,054 |

| Cast iron | < 180 HB | - | 38 | 0,035 | 0,048 |

| > 180 HB | - | 30 | 0,035 | 0,048 | |

| Nodular graphite, malleable iron | > 180 HB | - | 30 | 0,035 | 0,048 |

| > 260 HB | E | 25 | 0,035 | 0,048 | |

| Legend | ||

| E = emulsion | ae = 0.5xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||