Solid carbide end mill Speedcut, ultra-hard steel 68 HRC, extra long

End mill SC Ultra HRC WN 4xD/2xD 50° TiAlN-S HA

CTR-SC-SP-WN-HS-EL-TNS-HA-D5,0MM

Art.-no. 5443300872

EAN 4055375919651

Price for selected packaging unit

Exclusively for trade customers

Register now and access more than 125,000 products

Especially suited to machining hardened and high-strength steels. High rigidity allows for high feed rates and long service life, high helix angle produces an excellent surface finish on the workpiece. The end mill is used for peripheral milling (finishing). At shallow depths, front cutting is also possible by reducing the feed rate by 50 %.

Product information

Datasheets(X)

| |

Product code | 7287 |

Material to be processed | Cast metal, Hard and tough material |

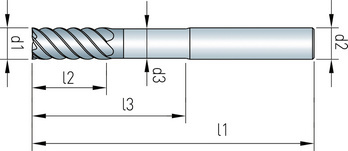

Diameter (d1) | 5 mm |

Shank diameter (d2) | 6 mm |

Clearance diameter (d3) | 4.7 mm |

Standards | CS |

Construction length | Extra long |

Shank style | Cylindrical DIN 6535-HA |

Cutting material | SC |

Surface | TiAlN-S |

Coolant supply | External |

Twist angle | 50° |

Length (l1) | 62 mm |

Cutting edge length (l2) | 13 mm |

Clearance length (l3) | 25 mm |

Number of cutting edges (Z) | 6 PCS |

Corner chamfer | 0.05 mm |

Tolerance of cutting edge diameter | e8 |

Tolerance of shank diameter | h5 |

Material of sub-group | Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Steels > 45 HRC |

| Cutting values for finishing contour | ||||||||

| For dia. 4-10 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 4 | Dia. 5 | Dia. 6 | Dia. 8 | Dia. 10 | ||||

| Tool steels | 1100-1400 N/mm² | T | 170 | 0,010 | 0,015 | 0,020 | 0,025 | 0,030 |

| Hardened steels | 40-48 HRC | T | 150 | 0,010 | 0,015 | 0,020 | 0,030 | 0,035 |

| 48-55 HRC | T | 135 | 0,010 | 0,015 | 0,020 | 0,025 | 0,030 | |

| 55-60 HRC | T | 120 | 0,008 | 0,012 | 0,015 | 0,025 | 0,030 | |

| 60-68 HRC | T | 80 | 0,008 | 0,012 | 0,015 | 0,020 | 0,025 | |

| Wear-resistant constructional steel | 1350 N/mm² | T | 170 | 0,010 | 0,015 | 0,020 | 0,025 | 0,025 |

| 1800 N/mm² | T | 145 | 0,010 | 0,015 | 0,020 | 0,025 | 0,025 | |

| Cast iron | < 180 HB | T | 200 | 0,015 | 0,022 | 0,030 | 0,040 | 0,055 |

| > 180 HB | T | 160 | 0,015 | 0,022 | 0,030 | 0,040 | 0,050 | |

| Nodular graphite, malleable iron | > 180 HB | T | 190 | 0,015 | 0,022 | 0,030 | 0,040 | 0,055 |

| > 260 HB | T | 170 | 0,015 | 0,022 | 0,030 | 0,040 | 0,050 | |

| Legend | ||

| T= dry | ae = 0.02xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/z] | ap = 1.5xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The cutting speeds listed refer to all tool types according to DIN 6527K or DIN6527L. For XL Series end mills, it is recommended to reduce the cutting speed by 30%. | ||

| Cutting values for finishing contour | |||||||

| For dia. 12-20 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| Dia. 12 | Dia. 14 | Dia. 16 | Dia. 20 | ||||

| Tool steels | 1100-1400 N/mm² | T | 170 | 0,035 | 0,035 | 0,040 | 0,045 |

| Hardened steels | 40-48 HRC | T | 150 | 0,040 | 0,045 | 0,050 | 0,060 |

| 48-55 HRC | T | 135 | 0,035 | 0,040 | 0,045 | 0,055 | |

| 55-60 HRC | T | 120 | 0,035 | 0,040 | 0,045 | 0,050 | |

| 60-68 HRC | T | 80 | 0,030 | 0,030 | 0,035 | 0,040 | |

| Wear-resistant constructional steel | 1350 N/mm² | T | 170 | 0,035 | 0,035 | 0,040 | 0,045 |

| 1800 N/mm² | T | 145 | 0,035 | 0,035 | 0,040 | 0,040 | |

| Cast iron | < 180 HB | T | 200 | 0,065 | 0,070 | 0,080 | 0,100 |

| > 180 HB | T | 160 | 0,060 | 0,065 | 0,070 | 0,090 | |

| Nodular graphite, malleable iron | > 180 HB | T | 190 | 0,065 | 0,070 | 0,080 | 0,100 |

| > 260 HB | T | 170 | 0,060 | 0,065 | 0,070 | 0,090 | |