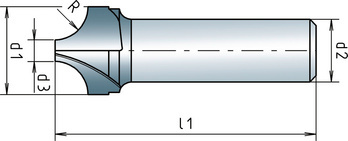

Solid carbide quarter-round profile cutter

Quarter circle profile cutter SC WN Z4 type N HA

QURTCRCLCTR-WN-SC-D32,0X10,0MM

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 6415 |

Material to be processed | Steel, Cast metal, Stainless steel, Aluminium |

Corner radius (R) | 10 mm |

Diameter (d1) | 32 mm |

Shank diameter (d2) | 20 mm |

Clearance diameter (d3) | 12 mm |

Standards | CS |

Shank style | Cylindrical DIN 6535-HA |

Cutting material | SC |

Surface | Plain |

Length (l1) | 85 mm |

Number of cutting edges (Z) | 4 PCS |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Aluminium |

| Cutting values |