Universal window sealing tape Euraseal U-305

Universal window sealing tape Euraseal U-305

WNDWSEALTPE-(U-305)-EASY-FSA-W70MM-L40M

Art.-no. 0875594070

EAN 4061975344847

Register now and access more than 125,000 products

Very high adhesive strength due to special acrylate adhesive on common substrates and frame materials (see instructions)

Free zone without adhesive ensures improved diffusion behaviour and compensates for component movements

Variable sd value of the membrane provides particularly good drying of the joint

- Reduces the risk of building damage caused by moisture and mould in the structure

- Increases the performance of the insulating material

Extremely wide range of applications

- Tape can be used for sealing both indoors and outdoors

- Due to the double-sided adhesive strips, the tape can be applied either on the same side or on alternating sides

- Very easy to use thanks to the high-quality, flexible fleece fabric

- Suitable for quality-controlled installation in accordance with the requirements of the German RAL quality assurance association for windows and doors

- Easy to plaster over

On mineral and highly absorbent surfaces, use an adhesion primer spray or butyl/bitumen primer.

Window sealing tape Universal Euraseal U-305 can be combined:

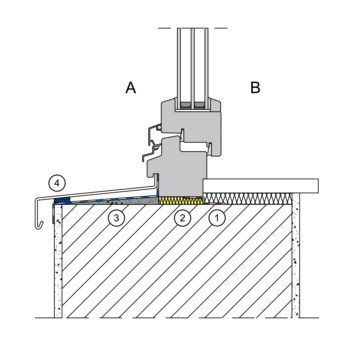

- Indoors: Window sealing tape Universal Euraseal U-305/exterior: VKP®Plus

- Indoors: Perfect neutral silicone/exterior: Window sealing tape Universal Euraseal U-305

- Indoors: Window sealing tape Universal Euraseal U-305/exterior: Window sealing tape Universal Euraseal U-305

Form the outer seal of the lower connection in the shape of a tray. (sloping outwards).

Datasheets(X)

For sealing window and door joints in new buildings and redevelopment projects

- Suitable for use with a wide range of common wall and window frame materials such as concrete, calcium silicate block, wooden surfaces, OSB boards, gypsum plasterboards, gypsum fibreboards, hard PVC and metal surfaces (see instructions)

- Pretreat mineral and highly absorbent surfaces with Würth spray primer or butyl primer

- The surfaces must be dry and free from dust and grease, promote adhesion and be capable of bearing loads. Pretreat mineral and highly absorbent surfaces with Würth spray primer or butyl primer

- The reveal must have a smooth coating in accordance with DIN 4108-7 in order for Universal Euraseal U-305 window sealing tape to be applied.

- Good adhesion is usually possible on concrete, calcium silicate block, wooden surfaces, OSB boards, gypsum plasterboards, gypsum fibreboards, hard PVC and metal surfaces

- Unroll the sealing tape and cut it to size, including approx. 5 cm of additional length (measured from the element to be glued).

- Installation on windows: Remove the protective film from the self-adhesive strip and press the window sealing tape firmly onto the blind frame using a pressure roller. For adhesion to the outside, follow the same process as for the inside.

- Proceed in the same way for all areas to be sealed.

- Align and secure the element, then use PURlogic PU foam to completely fill the space between the element and the building structure.

- Installation on masonry: Remove the protective film either completely or partially as required from the fully bonded side. Secure to the wall and press on firmly using a pressure roller.

- Corners are formed by creating loops or overlaps. Make sure that the strips of tape are fully sealed in the corner and overlap areas.

- The fleece-laminated side can be plastered with commercially available plaster mortars. The fleece-laminated side remains visible. (Trowel logo).

- Form the outer seal of the lower connection in the shape of a tray. (sloping outwards).

- Pass the side seal over the bottom seal.

- Small defects can be closed up using Plus flexible tape adhesive.

- When plastering the window sealing tape, observe the regulations of the current "Verputzen von Fensteranschlussfolien" (Plastering of Window Connection Films) plasterer's guidelines.

- For doors and floor-level elements, observe the regulations of DIN 18533.

- To protect the functional membrane, the film should be secured on both sides as soon as possible after installation (max. 24 hours).

- When used at 0 to -5 °C, the initial adhesive strength is reduced. It is still possible to install the product at these temperatures, but a longer contact time is required in order to achieve a high final strength.

| |

Colour | White |

Backing material | PET fleece |

Width | 70 mm |

Thickness | 0.4 mm |

Length of roll | 40 m |

Min./max. processing temperature | -5 to 30 °C |

Min./max. temperature resistance | -30 to 100 °C |

Min. resistance against driving rain (pressure)/conditions | 1200 Pa / in accordance with DIN EN 1027 |

Building material class/conditions | E - Normally inflammable / in accordance with DIN EN 13501-1 |

Ultraviolet resistance | 12 months |

Max. outdoor exposure | 3 Month |

Shelf life from production/conditions | 12 Month / at 15°C to 20°C |

Sustainability | Pollutants / Emissions |

| Water vapour diffusion-equivalent air layer thickness | |

| Humidity 0–17%: | > 5.5 m |

| Humidity 17–50%: | > 2.6 m |

| Humidity > 90% | < 1 m |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!