VKP® PLUS sealing tape

Sealing tape, VKP PLUS

SEALTPE-(VKP-PLUS)-10/3-GREY-10M

Art.-no. 087502103

EAN 4024835895026

Register now and access more than 125,000 products

Tested sealing properties over 600 Pa, BG1 and BGR in accordance with DIN 18542:2020-04

Tested and certified resistance to driving rain by complying with the necessary test parameters.

A product from the Würth Sealing System

The individual product components from the Würth Sealing System are matched to each other with regard to material compatibility.

Excellent ecological compatibility

Tested ecological safety according to GEV test method (class EC 1 PLUS).

Solvent-free and EMICODE EC1 plus

Safe to humans and the environment

Bridging of large joint differences that will withstand driving rain

Due to the tape's large tolerance, component movements can be compensated and common construction tolerances can be bridged more effectively. This reduces the number of tape sizes used.

Water-repellent, yet permeable to water vapour

When compressed accordingly, the tape seals against driving rain; however, due to its permeability to vapour, it provides excellent compensation of moisture.

Perimeter sealing systems according to ift certification programme QM360: 2014, reg. no. 188 7050098

EMICODE EC1plus: Very low emission – the EMICODE classification system characterises the environmental and health compatibility of construction products. The lowest-emission products bear the EC1plus mark.

The recovery times are not subject to a certain specification and are only based on empirical values. They are dependent on the storage time and the storage and processing temperature. The longer the storage times and the lower the processing temperature, the longer the recovery times.

In the case of joint sealing tapes freely exposed to the weather, environmental influences can cause discolouration and patina formation on the surface of the tape. This does not constitute a technical defect and does not diminish the technical characteristics of the tape, provided that the application area of the tape is maintained at the expected maximum joint width.

Resistance to UV and weathering can only be ensured if installation is performed such that it will withstand driving rain.

Datasheets(X)

Function:

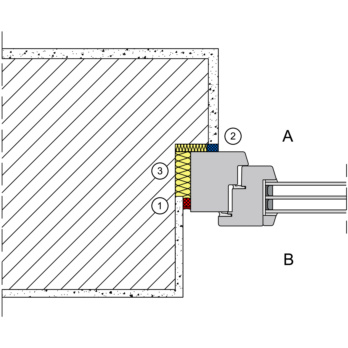

The pre-compressed, one-sided self-adhesive VKP Plus sealing tape seals joints reliably and permanently. After the compression is released, the sealing tape develops a resilience that presses firmly against the joint edges and compensates for uneven areas of the joint. Depending on the installation period, the non-adhesive side develops a slight anchoring on the adjacent building material.

In construction:

Expansion joints, seals between prefabricated components, window and door connections, partition walls.

General industry:

Container construction, air-conditioning system construction, machine and apparatus construction etc.

- Clean the joint/surface of oil, grease and loose material

- Remove the masking paper from the sealing tape

- Affix the sealing tape to the surface, or lay directly from the roll into the joint and lightly press on

- Cut off approx. 2 cm from the beginning and end of the tape

- Lay the tape so it does not overlap; do not lay around corners

- Allow approx. 2 cm/m of extra length when cutting the tape to size

- A sealing function is not provided under the influence of standing water

- Please observe the specified joint width. Only by doing so can resistance to driving rain and UV be guaranteed.

| |

Colour | Grey |

Chemical basis | Fine open-cell polyurethane foam |

Width | 10 mm |

Min./max. joint width for watertightness in driving rain | 3-5 mm |

Length of roll | 10.0 m |

Min. resistance against driving rain (pressure)/conditions | 600 Pa / in accordance with DIN 18542-BG1 |

Building material class/conditions | B1 - Of low flammability / in accordance with DIN 4102 |

Max. water-vapour diffusion resistance factor value µ | 100 |

Ultraviolet resistance | Yes, when installed to be resistant to driving rain |

Min./max. temperature resistance | -30 to 90 °C |

Shelf life from production | 24 Month |

Conditions to maintain shelf life from production | at 5°C to 25°C |

Sustainability | Pollutants / Emissions |

| Time required for expansion in the joint* | |

| 0°C | Up to 10 days |

| 10°C | 48 hours |

| 20°C | 3 hours |

| 30°C | 10 minutes |

| * Caution: The reset times are not subject to a certain specification and are only based on empirical values. They are dependent on the storage time and the storage and processing temperature. The longer the storage times and the lower the processing temperature, the longer the reset times. | |