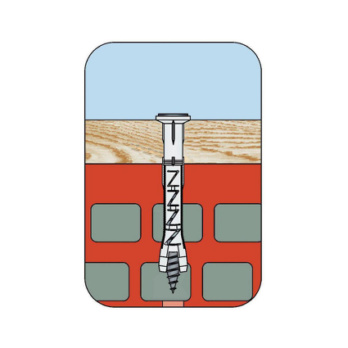

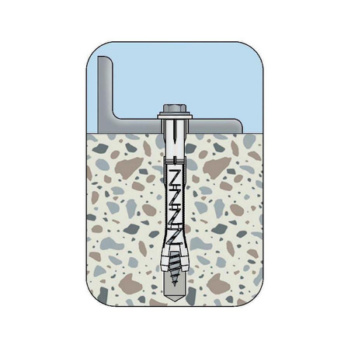

W-RD plastic frame anchor with collar, in natural colour

Plastic frame anchor, W-RD with collar

ANC-(W-RD)-PLA-W.COLLAR-50-8X120

Art.-no. 0912808105

EAN 4047376504424

Register now and access more than 125,000 products

Installation and application

- In-place installation facilitates and speeds up installation

- Time savings due to immediate load-bearing capacity

- Virtually no spinning of the anchor sleeve due to low installation torque and expansion

- Hammer-in stop prevents premature expansion of the anchor during installation

- Can be used outdoors or in wet rooms in conjunction with a stainless steel screw

- Anchorage via friction locking between anchor sleeve and base material

Performance and reliability

- Strong anti-rotation lock

- High working loads due to expansion in four directions

- Improved load transmission through even, continuous load transfer across the entire expansion area

Material properties

- Anchor sleeve made of high-quality polyamide

- Halogen and silicone free

- Thermally stable from -40 °C to +80 °C

- Inconspicuous natural colour without additional dyes or coatings

Performance data determined in Würth test laboratory

- The screw length should correspond to the length of the anchor plus the diameter of the screw

- Use wood or chipboard screws without an optimised thread tip (drill tip, counter thread, ring thread etc.)

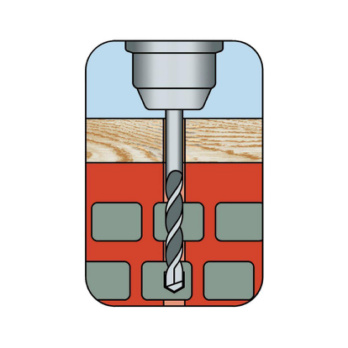

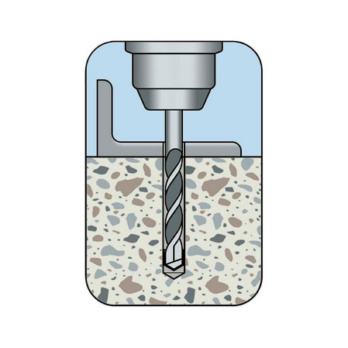

Create the drill hole

Create the drill hole

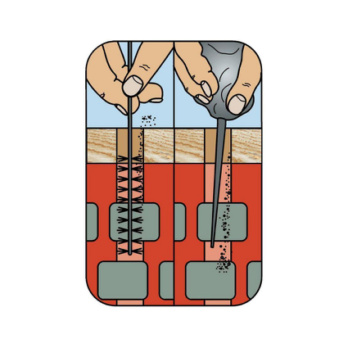

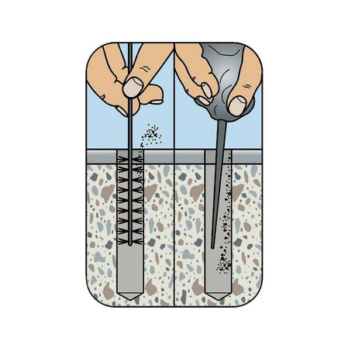

Clean the drill hole

Clean the drill hole

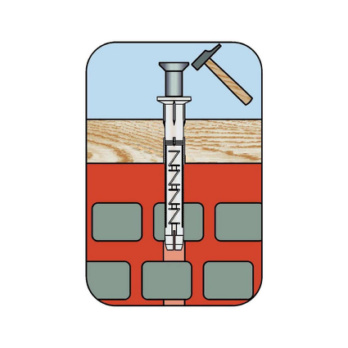

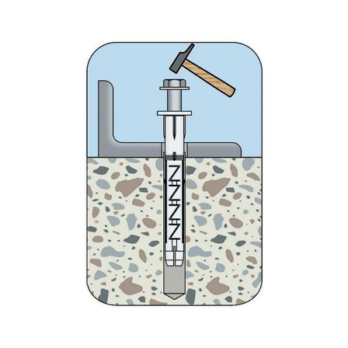

Set anchor and screw

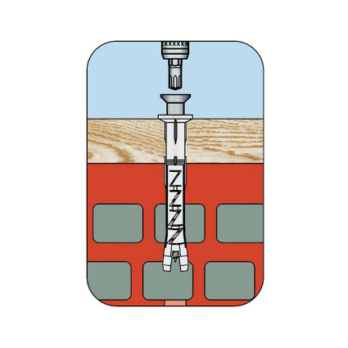

Screw in the screw

Screw in screw until flush

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

Set anchor and screw

Screw in the screw

Screw in screw until flush

Datasheets(X)

- Suitable for light and medium loads

- Suitable for fastening wardrobes, curtain rails, wall shelves, lightweight wall cupboards, wall-mounted cabinets, mirrors, picture frames, cable clamps, electrical switches, washbasins, wooden beams, wooden laths, metal rails, angle brackets, profiles, information signs etc.

- Suitable for attaching components in conjunction with wood or chipboard screws without an optimised thread tip (e.g. drill tip, counter thread, ring thread etc.)

- Secondary attachments: Concrete and solid and perforated block masonry

- Suitable for anchoring in normal weight concrete, masonry walls (solid brick, solid sand-lime blocks, vertically perforated brick, hollow sand-lime blocks, hollow lightweight concrete blocks, solid lightweight concrete blocks)

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

- Drill cuttings must be removed from the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Anchor diameter | 8 mm |

Anchor length (l) | 120 mm |

Max. attachment height (t fix) | 50 mm |

Nominal drill-bit diameter (d 0) | 8 mm |

Through-hole in the component to be connected (d f) | 8.5 mm |

Screw diameter | 6 mm |

Drill hole depth (h 0) | 80 mm |

Drill hole depth (h 1) | 80 mm |

Type description | W-RD 10, with collar |

| Performance data | ||||||

| Anchor diameter [mm] | 6 | 8 | 8 | 10 | ||

| Anchoring depth hef [mm] | 50 | 50 | 70 | 70 | ||

| Permissible load1) (Tensile, transverse and oblique pull at every angle) | Concrete | Frec [kN] ≥ C20/251) | 0,4 | 0,4 | 0,5 | 0,5 |

| Solid brick Mz, EN 771-1, DIN 105 ≥ NF (≥ 240 x 115 x 71) | Frec [kN] ≥ Mz 361) | 0,2 | 0,3 | 0,4 | 0,3 | |

| Solid sand-lime brick KS, EN 771-2, DIN 106 ≥ NF (≥ 240 x 115 x 71) | Frec [kN] ≥ KS 201) | 0,4 | 0,4 | 0,5 | 0,5 | |

| Solid bricks and solid blocks made of standard concrete EN 771-3, DIN 18153 ≥ NF (≥ 240 x 115 x 71) | Frec [kN] ≥ Vbn121) | 0,4 | 0,4 | 0,6 | 0,6 | |

| Solid bricks and solid blocks made of lightweight concrete EN 771-3, DIN V 18152-100 ≥ NF (≥ 240 x 115 x 71) | Frec [kN] ≥ V41) | 0,1 | 0,2 | 0,3 | 0,3 | |

| Vertically perforated brick HLz, EN 771-1, DIN 105 ≥ 2DF (≥ 240 x 115 x113) | Frec [kN] ≥ Hlz 201) | 0,1 | 0,2 | 0,2 | 0,1 | |

| Hollow sand-lime brick KSL, EN 771-2, DIN 106 ≥ 2DF (≥ 240 x 115 x113) | Frec [kN] ≥ KSL 61) | 0,1 | 0,2 | 0,4 | 0,4 | |

| Hollow block made of lightweight concrete 3K Hbl, EN 771-3, DIN 18151 ≥ 16DF (≥ 497 x 237 x 241) | Frec [kN] ≥ Hbl 61) | 0,1 | 0,2 | 0,1 | 0,3 | |

| 1) The recommended loads were obtained with the plug screw with countersunk head in accordance with DIN 97. | ||||||

Characteristic values | ||||||

Concrete | Axis distance | s ≥ [mm] | 100 | 100 | 100 | 100 |

Edge spacing | c ≥ [mm] | 70 | 70 | 70 | 140 | |

Minimum component thickness | hmin ≥ [mm] | 100 | 100 | 100 | 100 | |

Masonry | Axis distance | s ≥ [mm] | 250 | 250 | 250 | 250 |

Edge spacing | c ≥ [mm] | 100 | 100 | 100 | 100 | |

Minimum component thickness | hmin ≥ [mm] | 115 | 115 | 115 | 115 | |

Nominal drill diameter2) | d0 [mm] | 6 | 8 | 8 | 10 | |

Drill hole depth | h0 ≥ [mm] | 60 | 60 | 80 | 80 | |

Anchoring depth3) | hnom ≥ [mm] | 50 | 50 | 70 | 70 | |

Through hole in component being connected | df ≤ [mm] | 6,5 | 8,5 | 8,5 | 10,5 | |

| 1) The recommended loads were obtained with the plug screw with countersunk head in accordance with DIN 97 (art. no. 0157 0. …). 2) If the drilling hole is created in the perforated brick with impact and hammer action, the load capacity is reduced. 3) The anchors must be positioned in such a way that the spreading part is anchored in the web of the stone. | ||||||