W-UR 6 SymCon plastic frame fixing with zinc plated steel countersunk head screw and SymCon thread

Plastic frame anchor, W-UR 6 SymCon, cntrsnk. head

ANC-(W-UR SYM)-PLA-AW20-(A2K)-30-6X80

Art.-no. 0912806403

EAN 4050642732803

Register now and access more than 125,000 products

Secure connections

- Virtually no spinning of the anchor sleeve due to low installation torque and expansion

- Reliable follow-up expansion capability due to ingenious anchor geometry

- Virtually no undercutting due to optimal compression of the anchor sleeve by screwing in the screw

Minimal installation work

- Improved load transmission through even, continuous load transfer across the entire expansion area

- Anchorage via friction locking between anchor sleeve and base material

- Hammer-in stop prevents premature expansion of the anchor during installation

- Minimal installation work because the anchor sleeve and special screw are pre-assembled

- Anchor sleeve made of high-quality polyamide

W-UR 6 SymCon and W-UR F 6 SymCon (galvanised steel): European Technical Approval ETA-11/0309.

The anchor has European Technical Approval for use in multiple attachment of non-load-bearing systems (e.g. suspended ceilings etc.).

- Anchoring base with approval: Standard concrete ≥ C12/15

- Anchoring bases without approval: Solid brick, solid sand-lime brick, vertically perforated brick, hollow sand-lime brick, hollow lightweight concrete blocks, solid bricks and blocks made of lightweight concrete

- Installation temperatures: Temperature of anchoring base:≥ –20°C Temperature of wall plug body:≥ 0°C

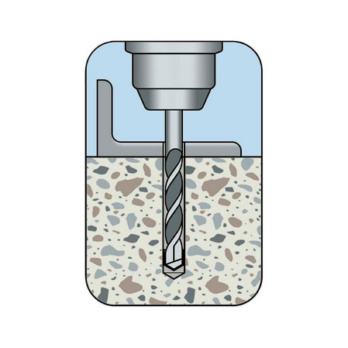

Create the drill hole

Create the drill hole

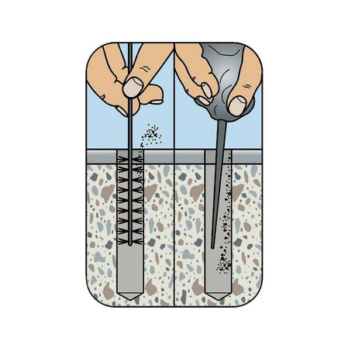

Clean the drill hole

Clean the drill hole

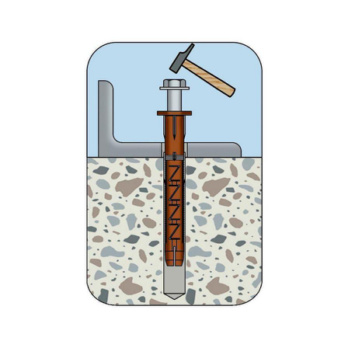

Set anchor and screw

Set anchor and screw

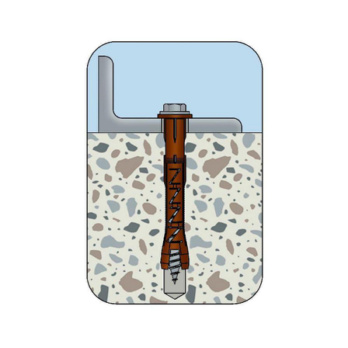

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

Datasheets(X)

CAD data (available after login)

Suitable for fastening ceiling substructures made of wood or steel, wooden laths, metal rails, suspended ceilings, angle brackets, profiles etc.

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

- Drill cuttings must be removed from the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Anchor diameter | 6 mm |

Anchor length (l) | 80 mm |

Nominal drill-bit diameter (d 0) | 6 mm |

Through-hole in the component to be connected (d f) | 6.5 mm |

Material of screw | Steel |

Internal drive | AW20 |

Surface of the screw | Zinc plated |

Drill hole depth (h 1) | 60 mm |

Approval | ETA-11/0309 |

Type description | W-UR 6 SymCon, countersunk head screw |

| Performance data: Concrete, multiple attachment of non-load-bearing systems | |||

| Anchor diameter | [mm] | W-UR 6 SymCon | |

| Embedment depth of the anchor sleeve | hnom [mm] | 50 | |

| Centric tension load1) for individual anchors or an anchor group | Nperm = C12/15 [kN] | 30°C2)/50°C3) | 0,79 |

| Nperm ≥ C16/20 [kN] | 30°C2)/50°C3) | 0,79 | |

| Shear load1) for individual anchors or an anchor group | Vperm | [kN] | 2,05 |

| Minimum member thickness | hmin | [mm] | 90 |

| Minimum axis distance4) | smin [mm] | C12/15 | 60 |

| ≥ C16/20 | 40 | ||

| Minimum edge distance4) | cmin [mm] | C12/15 | 60 |

| ≥ C16/20 | 40 | ||

| Characteristic edge distance | ccr,N [mm] | C12/15 | 60 |

| ≥ C16/20 | 40 | ||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and transverse loads, please refer to ETAG 020 Appendix C. 2) Maximum long-term temperature. 3) Maximum short-term temperature. 4) The permissible load must be reduced. | |||

| Installation parameters: Concrete | ||

| Anchor diameter [mm] | W-UR 6 SymCon | |

| Nominal drill diameter | d0 [mm] | 6 |

| Drill cutting dia. | dcut ≤ [mm] | 6,4 |

| Drill hole depth | h1 ≥ [mm] | 60 |

| Embedment depth of the anchor sleeve | hnom [mm] | 50 |

| Through hole in the attachment | df ≤ [mm] | 6,5 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!