W-UR F 6 SymCon plastic frame fixing with zinc plated steel raised countersunk head screw, flat collar and SymCon thread

Plastic frame anchor W-UR 6 SymCon pan head

ANC-(W-URSYM)-PLA-PANHD-AW20-A2K-10-6X60

Art.-no. 0912806802

EAN 4050642658837

Price for selected packaging unit

Exclusively for trade customers

Register now and access more than 125,000 products

Special anchor geometry and immediate load-bearing capacity with ETA assessment for anchors in a redundant non-structural system in concrete

Reliable geometry and functionality

- Virtually no spinning of the anchor sleeve due to low installation torque and expansion

- Reliable follow-up expansion capability due to ingenious anchor geometry

- Virtually no undercutting due to optimal compression of the anchor sleeve by screwing in the screw

Easy to install

- Improved load transmission through even, continuous load transfer across the entire expansion area

- Anchorage via friction locking between anchor sleeve and base material

- Hammer-in stop prevents premature expansion of the anchor during installation

- Minimal installation work because the anchor sleeve and special screw are pre-assembled

- Anchor sleeve made of high-quality polyamide

Proof of Performance

W-UR 6 SymCon and W-UR F 6 SymCon (galvanised steel): European Technical Approval ETA-11/0309

Application area

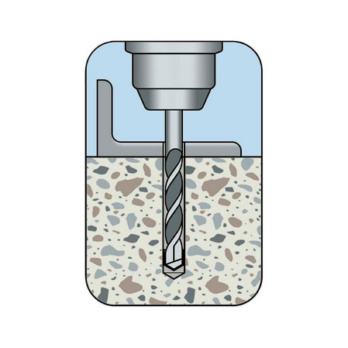

Create the drill hole

Create the drill hole

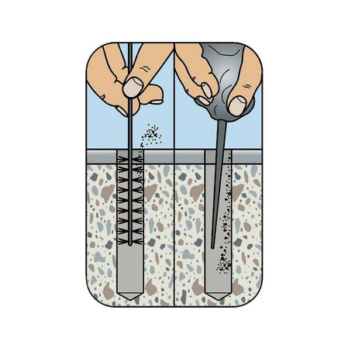

Clean the drill hole

Clean the drill hole

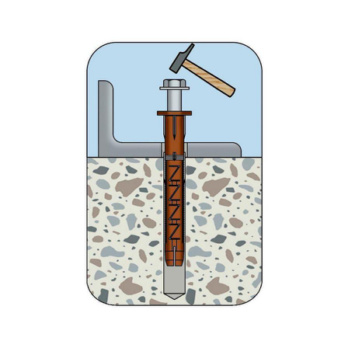

Set anchor and screw

Set anchor and screw

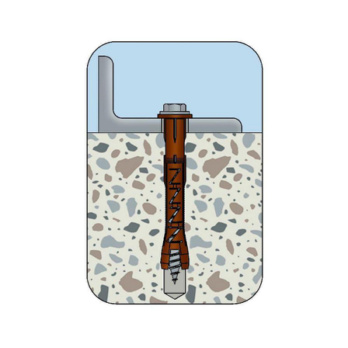

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

Product information

Datasheets(X)

CAD data (available after login)

Application area

- The anchor can be used with a European technical approval for anchors in a redundant non-structural system in non-load-bearing systems (e.g. suspended ceilings etc.)

- Suitable for base materials with approval for normal weight concrete ≥ C12/15

- Suitable for base materials without approval for solid brick, solid sand-lime blocks, vertically perforated brick, hollow sand-lime blocks, hollow lightweight concrete blocks, solid lightweight concrete blocks

- Suitable for fastening ceiling substructures made of wood or steel, wooden laths, metal rails, suspended ceilings, cable conduits, angle brackets, profiles etc.

Instructions

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

- Drill cuttings must be removed from the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Anchor diameter | 6 mm |

Anchor length (l) | 60 mm |

Nominal drill-bit diameter (d 0) | 6 mm |

Through-hole in the component to be connected (d f) | 6.5 mm |

Fire resistance rating | F30 |

Material of screw | Steel |

Internal drive | AW20 |

Surface of the screw | Zinc plated |

Head type | Pan head |

Drill hole depth (h 1) | 60 mm |

Approval | ETA-11/0309 |

Type description | W-UR F 6 SymCon, pan head screw |

| Performance data: Concrete, multiple attachment of non-load-bearing systems | |||

| Anchor diameter | [mm] | W-UR 6 SymCon | |

| Setting depth of the wall plug body | hnom [mm] | 50 | |

| Central tensile load1) for single anchors or dowel group | Nperm = C12/15 [kN] | 30°C2)/50°C3) | 0,79 |

| Nperm ≥ C16/20 [kN] | 30°C2)/50°C3) | 0,79 | |

| Shear load1) for single anchors or dowel group | Vperm | [kN] | 2,05 |

| Minimum component thickness | hmin | [mm] | 90 |

| Minimum axis distance4) | smin [mm] | C12/15 | 60 |

| ≥ C16/20 | 40 | ||

| Minimum edge spacing4) | cmin [mm] | C12/15 | 60 |

| ≥ C16/20 | 40 | ||

| Characteristic edge spacing | ccr,N [mm] | C12/15 | 60 |

| ≥ C16/20 | 40 | ||

| 1) The partial safety coefficients of the resistances as well as a partial safety coefficient of the effects of γF = 1.4 regulated in the approval are taken into account. For the combination of tensile and transverse loads, please refer to ETAG 020 Appendix C. 2) Maximum long-term temperature. 3) Maximum short-term temperature. 4) The permissible load must be reduced. | |||

| Installation parameters: Concrete | ||

| Anchor diameter [mm] | W-UR 6 SymCon | |

| Nominal drill diameter | d0 [mm] | 6 |

| Drill cutting dia. | dcut ≤ [mm] | 6,4 |

| Drill hole depth | h1 ≥ [mm] | 60 |

| Setting depth of the wall plug body | hnom [mm] | 50 |

| Through hole in attachment part | df ≤ [mm] | 6,5 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!