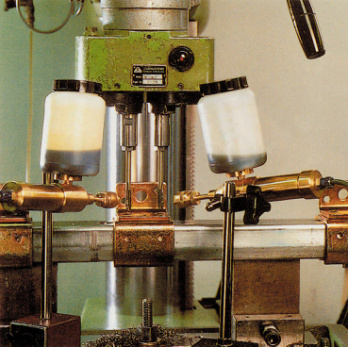

Cut and Cool Perfect drilling/cutting paste

Drilling and cutting paste CUT+COOL PERFECT

CUTPAST-DRILL-(CUT-COOL-PERFECT)-500ML

Register now and access more than 125,000 products

Safe and efficient to use

- Longer tool service life

- High corrosion protection

- Can be welded without advance cleaning for low quantities

Can be used as minimum quantity lubricant

Optimum performance, optimum results thanks to specifically matched components

Paste for the most challenging machining tasks

- Machining of highest-strength steels fully possible

- Horizontal and overhead applications entirely implementable

- Storage temperature: 5-40°C

- Storage class (VCI concept): 10

| Drilling and cutting oil | Drilling and cutting oil Perfect | Drilling and cutting paste Perfect | Drilling and cutting oil Eco | Drilling and cutting foam | Cutting oil DVGW | Cooling lubricant Ultra | Cooling lubricant Ultra HD | |

| Materials | ||||||||

| Machining processes | ||||||||

| Features | ||||||||

| Base material | Mineral oil | Mineral oil with synth. ester | Mineral oil with synth. ester | Synth. ester | Glycol and ester | Ester | Mineral oil | Mineral oil |

| Steel, alloyed steel | xx | xxx | xxx | xxx | xxx | xx | xx | xxx |

| High-alloy steel | xx | xxx | xxx | xxx | xxx | xx | xx | xxx |

| Cast iron, grey cast iron | xx | xxx | xxx | xx | xxx | x | xx | xxx |

| Carbide | xx | xxx | xxx | xx | xxx | x | x | xx |

| Non-ferrous base metal (copper, brass, etc.) | xx | xxx | xx | xxx | xxx | x | x | xx |

| Titanium | x | xxx | xxx | xx | xxx | x | x | xx |

| Magnesium | x | xxx | xxx | xx | xxx | x | x | xx |

| Aluminium, aluminium alloys | x | xxx | xxx | xx | xxx | x | xx | xxx |

| Lathing, automatic lathes | xx | xxx | x | x | x | x | xx | xxx |

| Drilling, countersinking, reaming | xx | xxx | xxx | xxx | xxx | x | xx | xx |

| Deep drilling | x | xxx | xxx | xx | xx | x | x | xx |

| Sawing | xx | xxx | xx | xxx | xxx | x | xx | xx |

| Thread cutting | xx | xxx | xxx | xxx | xxx | xx | xx | xx |

| Thread forming, rolling | xx | xxx | xxx | xxx | xxx | x | x | xx |

| Milling | x | xxx | x | xx | xx | x | xxx | |

| Sanding | x | xxx | x | x | x | x | xxx | xx |

| Forming, rolling, bending | x | xxx | xx | xx | xx | x | x | xx |

| Punching, fine punching | x | xx | xx | xx | x | x | x | |

| Broaching, toothing | x | xxx | xx | xxx | xxx | x | x | x |

| Viscosity (mm²/s) | 12 | 25 | Paste-like | 35 | n/a | 5 | 66 | 76 |

| Minimum quantity lubrication | ⎷ | ⎷ | ||||||

| Free from mandatory warning symbols | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Can be used upside down | ⎷ | ⎷ | ||||||

| DVGW-approved | ⎷ | |||||||

| Biodegradable/approved for use with food | ⎷ | |||||||

| Extremely high lubricating performance | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | |||

| Extremely long tool life | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ||

| Minimal smoking | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ||

| Extremely low consumption | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Good creeping properties | ⎷ | |||||||

| Free of boric acid | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Low-foaming | ⎷ | ⎷ | ||||||

| Extremely high microbial stability | ⎷ | ⎷ | ||||||

| Water hazard class | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 |

| Formaldehyde-free | ⎷ | ⎷ | ⎷ | ⎷ | ||||

| Extremely gentle on the skin (amine-free) | ⎷ | ⎷ | ⎷ | |||||

| xxx excellent suitability xx good suitability x less favourable suitability ⎷ applicable | ||||||||

Datasheets(X)

The drilling and cutting paste is particularly suitable for heavy-duty machining processes, such as high-strength hard steels, tool steel, ball bearing steel, CrNi alloys, and Hastelloy.

Apply the paste to the machining tool using a brush.

Contents | 500 ml |

Colour | Brown |

Chemical basis | Mineral oil with synthetic ester |

Density/conditions | 0.88 g/cm³ / at 20°C |

Shelf life from production | 36 Month |

Silicone-free | Yes |

Chlorine-free | Yes |

AOX-free | Yes |

Resin-free | Yes |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!