Hexagon nut, low profile, with clamping piece (non-metal insert) ISO 10511, steel, strength class 5, zinc-nickel-plated, black (ZNBHL)

ISO 10511 steel 05, zinc-nickel, black

NUT-HEX-ISO10511-05-WS18-(ZNBHL)-M12

Art.-no. 5162011512

EAN 4057708695706

Register now and access more than 125,000 products

Fasteners with a zinc-plated chromium (VI)-free zinc-nickel black coating (ZNBHL) are suitable for applications with a high risk of corrosion. The coating comprises a zinc-nickel alloy layer and a sealing coat (top coat with integrated lubricating particles).

Corrosion resistance:

- Diameter ≥ M2 – 360h*

- Diameter ≥ M4 – 480h*

- Diameter ≥ M10 – 720h*

- *No base metal corrosion at points without thread in salt spray mist testing according to DIN EN ISO 9227 NSS

Overview of advantages:

- Corrosion resistance of up to 720 hrs to base metal corrosion in accordance with DIN EN ISO 9227 NSS

- Chromium(VI)-free

- Adjusted friction coefficient range of 0.09 μ–0.14 μ due to top coat with integrated lubricating particles

- Thermal capacity up to 120°C

- Even coat distribution

- Functional and decorative

ISO 10511 replaces DIN 985 | There is some limited similarity | Thread M7, M18, M22, M27, M33 and threads with nominal diameter > M36 removed | Fine thread removed | Nut height changed | Width across flats changed for threads M10, M12 and M14 to 16, 18 and 21 mm | Strength classes changed to 04 and 05.

Datasheets(X)

| |

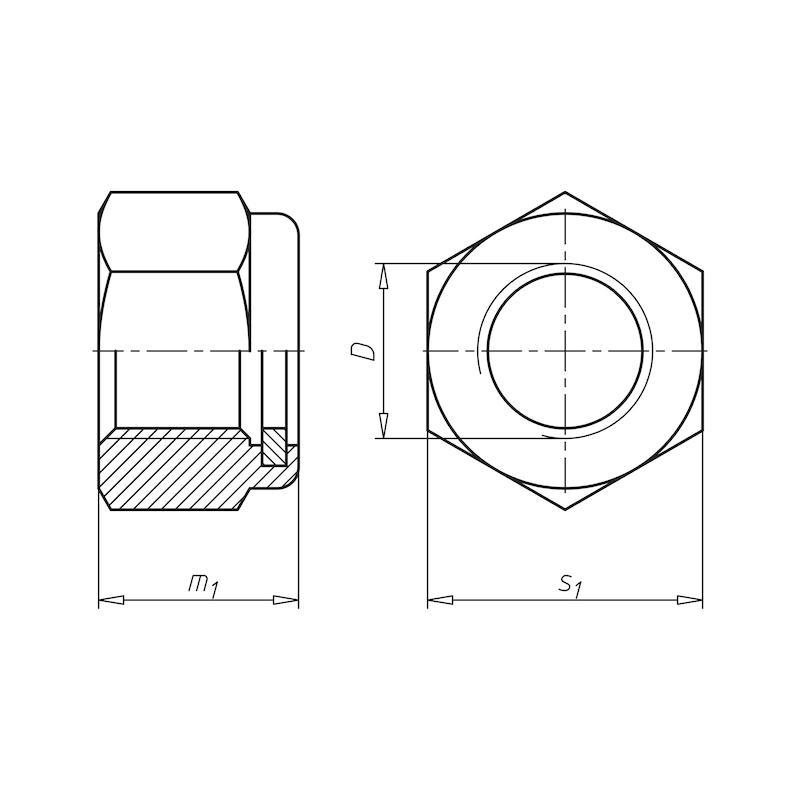

Thread type x nominal diameter (D) | M12 |

Height (m1) | 10.23 mm |

External drive (s1) | WS18 |

Standards | ISO 10511 |

Material | Steel |

Property class | 05 |

Surface | Zinc nickel black |

Corrosion protection period | 720 h |

RoHS-compliant | Yes |

Form | Low |

Locking device operating principle | Clamping part polyamide ring |

Locking function | Locking against loosening by clamping |