STC+ end mill Turbo-Twister-Uni, five-cutter, unequal twist gradient, 4xD

End mill STC+Turbo-Twister-Allround 4xD type N

ENDMIL-SHA-TTW-WN-XL-STC-UV-SD-HB-D12

Art.-no. 5443320404

EAN 4065233065529

Register now and access more than 125,000 products

One tool for virtually all materials

Solid machining process for all application needs

- Short chips due to several chip breakers and an extremely precise twist angle to the geometry / a helix angle that is precisely adjusted to the tool geometry

- The extremely robust core ensures significantly reduced vibrations and reduces the risk of tool breakage considerably

Easy to use in almost all modern CNC production processes

Wide cutting value range

Long service life thanks to newly developed SUPRADUR coating

- Extremely resistant special coating for a wide range of applications

- Optimum resistance to temperature changes increases process reliability even under the toughest conditions

- Ideal for wet and dry processing in almost all materials

Datasheets(X)

| |

Product code | 8004 |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Hard and tough material, Non-ferrous metal |

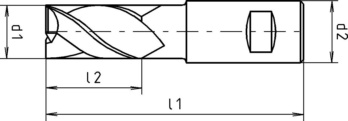

Diameter (d1) | 12 mm |

Shank diameter (d2) | 12 mm |

Standards | CS |

Construction length | Extra long |

Shank style | Cylindrical DIN 6535-HB |

Cutting material | SC |

Surface | SUPRADUR |

Coolant supply | External |

Twist angle | 40° Vario |

Length (l1) | 103 mm |

Cutting edge length (l2) | 50 mm |

Number of cutting edges (Z) | 5 PCS |

Corner chamfer | 0.05 mm |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys, Steels > 45 HRC, Copper, Brass, Aluminium |

| Legend | ||

| L = air | ae = 0.03xd1 - 0.20xd1 | |

| E = emulsion | ||

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/tooth] | ap = 4xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. Choosing the correct mount is a crucial factor in trochoidal processing. The best results were achieved with an IK Weldon tool holder (G2.5/18000rpm weighing grade). | ||

| Cutting values for Dynamic 2xd1 | ||||||

| For dia. 20 | ||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||

| Dia. 20 | ||||||

| Min. | Max. | Min. | Max. | |||

| General structural steels | < 500 N/mm² | L + E | 231 | 525 | 0,140 | 0,290 |

| 500-850 N/mm² | L + E | 187 | 425 | 0,130 | 0,270 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 425 | 0,130 | 0,270 |

| 850-1000 N/mm² | L + E | 176 | 400 | 0,120 | 0,240 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 182 | 413 | 0,140 | 0,290 |

| 700-850 N/mm² | L + E | 182 | 413 | 0,130 | 0,270 | |

| 850-1000 N/mm² | L + E | 182 | 413 | 0,120 | 0,240 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 400 | 0,120 | 0,240 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,090 | 0,180 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 525 | 0,140 | 0,290 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 400 | 0,120 | 0,240 |

| 850-1200 N/mm² | L + E | 154 | 350 | 0,100 | 0,210 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 400 | 0,120 | 0,240 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,090 | 0,180 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 425 | 0,120 | 0,240 |

| 850-1100 N/mm² | L + E | 176 | 400 | 0,100 | 0,210 | |

| 1100-1400 N/mm² | L + E | 176 | 400 | 0,100 | 0,210 | |

| 1080 (33HRC) | L + E | 176 | 400 | 0,100 | 0,210 | |

| High-speed steels | 850-1200 N/mm² | L + E | 105 | 238 | 0,100 | 0,210 |

| Spring steels | < 1200 N/mm² | L + E | 105 | 238 | 0,070 | 0,150 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 127 | 288 | 0,120 | 0,240 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 275 | 0,100 | 0,210 |

| < 850 N/mm² | E | 105 | 238 | 0,100 | 0,210 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 200 | 0,100 | 0,210 |

| Special alloys | < 1200 N/mm² | E | 72 | 163 | 0,090 | 0,200 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 150 | 0,100 | 0,210 |

| Aluminium, aluminium alloys | < 400 N/mm² | E | 400 | 550 | 0,140 | 0,280 |

| Aluminium, aluminium cast alloys < 10% | < 600 N/mm² | E | 300 | 450 | 0,130 | 0,260 |

| Aluminium, aluminium cast alloys > 10% Si | < 600 N/mm² | E | 150 | 250 | 0,130 | 0,260 |

| Copper, low-alloyed | < 450 N/mm² | E | 120 | 180 | 0,120 | 0,230 |

| Brass, short-chipping | < 600 N/mm² | E | 150 | 250 | 0,120 | 0,230 |

| Brass, long-chipping | < 600 N/mm² | E | 150 | 200 | 0,120 | 0,230 |

| Bronze, short-chipping | < 600 N/mm² | E | 150 | 200 | 0,120 | 0,230 |

| 650-850 N/mm² | E | 120 | 200 | 0,120 | 0,230 | |

| Bronze, long-chipping | < 850 N/mm² | E | 120 | 200 | 0,120 | 0,230 |

| Cutting values for Dynamic 4xd1 | ||||||||||

| For dia. 12–16 | ||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||||

| Dia. 12 | Dia. 14 | Dia. 16 | ||||||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||

| General structural steels | < 500 N/mm² | L + E | 231 | 525 | 0,100 | 0,210 | 0,110 | 0,220 | 0,120 | 0,250 |

| 500-850 N/mm² | L + E | 187 | 425 | 0,100 | 0,200 | 0,100 | 0,200 | 0,110 | 0,230 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 425 | 0,090 | 0,180 | 0,100 | 0,190 | 0,110 | 0,230 |

| 850-1000 N/mm² | L + E | 176 | 400 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,210 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 182 | 413 | 0,100 | 0,210 | 0,110 | 0,220 | 0,120 | 0,250 |

| 700-850 N/mm² | L + E | 182 | 413 | 0,100 | 0,200 | 0,110 | 0,210 | 0,110 | 0,230 | |

| 850-1000 N/mm² | L + E | 182 | 413 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,210 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 400 | 0,080 | 0,160 | 0,090 | 0,180 | 0,100 | 0,210 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,070 | 0,150 | 0,070 | 0,150 | 0,080 | 0,160 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 525 | 0,100 | 0,210 | 0,110 | 0,220 | 0,120 | 0,250 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 400 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,210 |

| 850-1200 N/mm² | L + E | 154 | 350 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 400 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,210 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,060 | 0,130 | 0,070 | 0,140 | 0,080 | 0,160 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 425 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,210 |

| 850-1100 N/mm² | L + E | 176 | 400 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 | |

| 1100-1400 N/mm² | L + E | 176 | 400 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 | |

| 1080 (33HRC) | L + E | 176 | 400 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 | |

| High-speed steels | 850-1200 N/mm² | L + E | 105 | 238 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 |

| Spring steels | < 1200 N/mm² | L + E | 105 | 238 | 0,060 | 0,120 | 0,060 | 0,120 | 0,060 | 0,130 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 127 | 288 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,210 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 275 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 |

| < 850 N/mm² | E | 105 | 238 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 200 | 0,080 | 0,160 | 0,080 | 0,170 | 0,090 | 0,180 |

| Special alloys | < 1200 N/mm² | E | 72 | 163 | 0,060 | 0,130 | 0,070 | 0,140 | 0,080 | 0,170 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 150 | 0,080 | 0,160 | 0,090 | 0,180 | 0,090 | 0,180 |

| Aluminium, aluminium alloys | < 400 N/mm² | E | 400 | 550 | 0,100 | 0,200 | 0,110 | 0,220 | 0,120 | 0,240 |

| Aluminium, aluminium cast alloys < 10% | < 600 N/mm² | E | 300 | 450 | 0,100 | 0,190 | 0,100 | 0,200 | 0,110 | 0,230 |

| Aluminium, aluminium cast alloys > 10% Si | < 600 N/mm² | E | 150 | 250 | 0,100 | 0,190 | 0,100 | 0,200 | 0,110 | 0,230 |

| Copper, low-alloyed | < 450 N/mm² | E | 120 | 180 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| Brass, short-chipping | < 600 N/mm² | E | 150 | 250 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| Brass, long-chipping | < 600 N/mm² | E | 150 | 200 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| Bronze, short-chipping | < 600 N/mm² | E | 150 | 200 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| 650-850 N/mm² | E | 120 | 200 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 | |

| Bronze, long-chipping | < 850 N/mm² | E | 120 | 200 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| Cutting values for static 4xd1 | ||||||||||

| For dia. 6–10 | ||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||||

| Dia. 6 | Dia. 8 | Dia. 10 | ||||||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||

| General structural steels | < 500 N/mm² | L + E | 231 | 504 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| 500-850 N/mm² | L + E | 187 | 408 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,150 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 408 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,150 |

| 850-1000 N/mm² | L + E | 176 | 384 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 182 | 396 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| 700-850 N/mm² | L + E | 182 | 396 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,160 | |

| 850-1000 N/mm² | L + E | 182 | 396 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 384 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 504 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 384 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| 850-1200 N/mm² | L + E | 154 | 336 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 384 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,040 | 0,080 | 0,040 | 0,090 | 0,060 | 0,110 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 408 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| 850-1100 N/mm² | L + E | 176 | 384 | 0,030 | 0,060 | 0,040 | 0,090 | 0,060 | 0,130 | |

| 1100-1400 N/mm² | L + E | 176 | 384 | 0,030 | 0,060 | 0,040 | 0,090 | 0,060 | 0,130 | |

| 1080 (33HRC) | L + E | 176 | 384 | 0,030 | 0,060 | 0,040 | 0,090 | 0,060 | 0,130 | |

| High-speed steels | 850-1200 N/mm² | L + E | 105 | 228 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| Spring steels | < 1200 N/mm² | L + E | 105 | 228 | 0,030 | 0,060 | 0,040 | 0,080 | 0,050 | 0,100 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 127 | 276 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 264 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| < 850 N/mm² | E | 105 | 228 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 192 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| Special alloys | < 1200 N/mm² | E | 72 | 156 | 0,030 | 0,060 | 0,040 | 0,090 | 0,060 | 0,110 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 144 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| Aluminium, aluminium alloys | < 400 N/mm² | E | 400 | 509 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| Aluminium, aluminium cast alloys < 10% | < 600 N/mm² | E | 300 | 416 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,150 |

| Aluminium, aluminium cast alloys > 10% Si | < 600 N/mm² | E | 150 | 231 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,150 |

| Copper, low-alloyed | < 450 N/mm² | E | 120 | 166 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Brass, short-chipping | < 600 N/mm² | E | 150 | 231 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Brass, long-chipping | < 600 N/mm² | E | 150 | 166 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Bronze, short-chipping | < 600 N/mm² | E | 150 | 166 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| 650-850 N/mm² | E | 120 | 166 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 | |

| Bronze, long-chipping | < 850 N/mm² | E | 120 | 166 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Cutting values for Dynamic 4xd1 | ||||||||||

| For dia. 6–10 | ||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||||

| Dia. 6 | Dia. 8 | Dia. 10 | ||||||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||

| General structural steels | < 500 N/mm² | L + E | 231 | 525 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| 500-850 N/mm² | L + E | 187 | 425 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,160 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 425 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,160 |

| 850-1000 N/mm² | L + E | 176 | 400 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,150 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 182 | 413 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| 700-850 N/mm² | L + E | 182 | 413 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,160 | |

| 850-1000 N/mm² | L + E | 182 | 413 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,150 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 400 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,150 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 525 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 400 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,150 |

| 850-1200 N/mm² | L + E | 154 | 350 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 400 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,150 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,040 | 0,080 | 0,040 | 0,090 | 0,060 | 0,120 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 425 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,150 |

| 850-1100 N/mm² | L + E | 176 | 400 | 0,030 | 0,070 | 0,040 | 0,090 | 0,060 | 0,130 | |

| 1100-1400 N/mm² | L + E | 176 | 400 | 0,030 | 0,070 | 0,040 | 0,090 | 0,060 | 0,130 | |

| 1080 (33HRC) | L + E | 176 | 400 | 0,030 | 0,070 | 0,040 | 0,090 | 0,060 | 0,130 | |

| High-speed steels | 850-1200 N/mm² | L + E | 105 | 238 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| Spring steels | < 1200 N/mm² | L + E | 105 | 238 | 0,030 | 0,070 | 0,040 | 0,080 | 0,050 | 0,100 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 127 | 288 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,150 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 275 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| < 850 N/mm² | E | 105 | 238 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 200 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| Special alloys | < 1200 N/mm² | E | 72 | 163 | 0,030 | 0,070 | 0,040 | 0,090 | 0,060 | 0,120 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 150 | 0,040 | 0,080 | 0,050 | 0,100 | 0,060 | 0,130 |

| Aluminium, aluminium alloys | < 400 N/mm² | E | 400 | 550 | 0,050 | 0,100 | 0,060 | 0,130 | 0,080 | 0,170 |

| Aluminium, aluminium cast alloys < 10% | < 600 N/mm² | E | 300 | 450 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,150 |

| Aluminium, aluminium cast alloys > 10% Si | < 600 N/mm² | E | 150 | 250 | 0,040 | 0,090 | 0,060 | 0,130 | 0,080 | 0,150 |

| Copper, low-alloyed | < 450 N/mm² | E | 120 | 180 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Brass, short-chipping | < 600 N/mm² | E | 150 | 250 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Brass, long-chipping | < 600 N/mm² | E | 150 | 200 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Bronze, short-chipping | < 600 N/mm² | E | 150 | 200 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| 650-850 N/mm² | E | 120 | 200 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 | |

| Bronze, long-chipping | < 850 N/mm² | E | 120 | 200 | 0,040 | 0,080 | 0,050 | 0,100 | 0,070 | 0,140 |

| Legend | ||

| L = air | ae = 0.03xd1 - 0.20xd1 | |

| E = emulsion | ||

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/tooth] | ap = 4xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. Choosing the correct mount is a crucial factor in trochoidal processing. The best results were achieved with an IK Weldon tool holder (G2.5/18000rpm weighing grade). | ||

| Cutting values for static 4xd1 | ||||||

| For 20 | ||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||

| Dia. 20 | ||||||

| Min. | Max. | Min. | Max. | |||

| General structural steels | < 500 N/mm² | L + E | 231 | 504 | 0,140 | 0,280 |

| 500-850 N/mm² | L + E | 187 | 408 | 0,130 | 0,260 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 408 | 0,130 | 0,260 |

| 850-1000 N/mm² | L + E | 176 | 384 | 0,120 | 0,230 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 182 | 396 | 0,140 | 0,280 |

| 700-850 N/mm² | L + E | 182 | 396 | 0,130 | 0,260 | |

| 850-1000 N/mm² | L + E | 182 | 396 | 0,120 | 0,230 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 384 | 0,120 | 0,230 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,090 | 0,170 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 504 | 0,140 | 0,280 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 384 | 0,120 | 0,230 |

| 850-1200 N/mm² | L + E | 154 | 336 | 0,100 | 0,200 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 384 | 0,120 | 0,230 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,090 | 0,170 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 408 | 0,120 | 0,230 |

| 850-1100 N/mm² | L + E | 176 | 384 | 0,100 | 0,200 | |

| 1100-1400 N/mm² | L + E | 176 | 384 | 0,100 | 0,200 | |

| 1080 (33HRC) | L + E | 176 | 384 | 0,100 | 0,200 | |

| High-speed steels | 850-1200 N/mm² | L + E | 105 | 228 | 0,100 | 0,200 |

| Spring steels | < 1200 N/mm² | L + E | 105 | 228 | 0,070 | 0,140 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 127 | 276 | 0,120 | 0,230 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 264 | 0,100 | 0,200 |

| < 850 N/mm² | E | 105 | 228 | 0,100 | 0,200 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 192 | 0,100 | 0,200 |

| Special alloys | < 1200 N/mm² | E | 72 | 156 | 0,090 | 0,190 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 144 | 0,100 | 0,200 |

| Aluminium, aluminium alloys | < 400 N/mm² | E | 400 | 509 | 0,140 | 0,280 |

| Aluminium, aluminium cast alloys < 10% | < 600 N/mm² | E | 300 | 416 | 0,130 | 0,260 |

| Aluminium, aluminium cast alloys > 10% Si | < 600 N/mm² | E | 150 | 231 | 0,130 | 0,260 |

| Copper, low-alloyed | < 450 N/mm² | E | 120 | 166 | 0,120 | 0,230 |

| Brass, short-chipping | < 600 N/mm² | E | 150 | 231 | 0,120 | 0,230 |

| Brass, long-chipping | < 600 N/mm² | E | 150 | 166 | 0,120 | 0,230 |

| Bronze, short-chipping | < 600 N/mm² | E | 150 | 166 | 0,120 | 0,230 |

| 650-850 N/mm² | E | 120 | 166 | 0,120 | 0,230 | |

| Bronze, long-chipping | < 850 N/mm² | E | 120 | 166 | 0,120 | 0,230 |

| Cutting values for static 4xd1 | ||||||||||

| For dia. 12–16 | ||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||||

| Dia. 12 | Dia. 14 | Dia. 16 | ||||||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | |||

| General structural steels | < 500 N/mm² | L + E | 231 | 504 | 0,100 | 0,200 | 0,110 | 0,220 | 0,120 | 0,240 |

| 500-850 N/mm² | L + E | 187 | 408 | 0,100 | 0,190 | 0,100 | 0,200 | 0,110 | 0,230 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 408 | 0,090 | 0,180 | 0,100 | 0,190 | 0,110 | 0,230 |

| 850-1000 N/mm² | L + E | 176 | 384 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 182 | 396 | 0,100 | 0,200 | 0,110 | 0,220 | 0,120 | 0,240 |

| 700-850 N/mm² | L + E | 182 | 396 | 0,100 | 0,190 | 0,110 | 0,210 | 0,110 | 0,230 | |

| 850-1000 N/mm² | L + E | 182 | 396 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,200 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 384 | 0,080 | 0,150 | 0,090 | 0,180 | 0,100 | 0,200 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,070 | 0,140 | 0,070 | 0,150 | 0,080 | 0,150 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 504 | 0,100 | 0,200 | 0,110 | 0,220 | 0,120 | 0,240 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 384 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,200 |

| 850-1200 N/mm² | L + E | 154 | 336 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 384 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,200 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,060 | 0,130 | 0,070 | 0,140 | 0,080 | 0,150 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 408 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,200 |

| 850-1100 N/mm² | L + E | 176 | 384 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 | |

| 1100-1400 N/mm² | L + E | 176 | 384 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 | |

| 1080 (33HRC) | L + E | 176 | 384 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 | |

| High-speed steels | 850-1200 N/mm² | L + E | 105 | 228 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 |

| Spring steels | < 1200 N/mm² | L + E | 105 | 228 | 0,060 | 0,110 | 0,060 | 0,120 | 0,060 | 0,130 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 127 | 276 | 0,080 | 0,170 | 0,090 | 0,180 | 0,100 | 0,200 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 264 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 |

| < 850 N/mm² | E | 105 | 228 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 192 | 0,080 | 0,160 | 0,080 | 0,170 | 0,090 | 0,180 |

| Special alloys | < 1200 N/mm² | E | 72 | 156 | 0,060 | 0,130 | 0,070 | 0,140 | 0,080 | 0,170 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 144 | 0,080 | 0,150 | 0,090 | 0,180 | 0,090 | 0,180 |

| Aluminium, aluminium alloys | < 400 N/mm² | E | 400 | 509 | 0,100 | 0,200 | 0,110 | 0,220 | 0,120 | 0,240 |

| Aluminium, aluminium cast alloys < 10% | < 600 N/mm² | E | 300 | 416 | 0,100 | 0,190 | 0,100 | 0,200 | 0,110 | 0,230 |

| Aluminium, aluminium cast alloys > 10% Si | < 600 N/mm² | E | 150 | 231 | 0,100 | 0,190 | 0,100 | 0,200 | 0,110 | 0,230 |

| Copper, low-alloyed | < 450 N/mm² | E | 120 | 166 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| Brass, short-chipping | < 600 N/mm² | E | 150 | 231 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| Brass, long-chipping | < 600 N/mm² | E | 150 | 166 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| Bronze, short-chipping | < 600 N/mm² | E | 150 | 166 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |

| 650-850 N/mm² | E | 120 | 166 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 | |

| Bronze, long-chipping | < 850 N/mm² | E | 120 | 166 | 0,080 | 0,170 | 0,900 | 0,180 | 0,100 | 0,200 |