nanoProtect EU+ HSCo 90° T=4 hexagon countersink for drill/drivers and tangential impact drivers

Countersink EU+ HSCo 90° 4 flt NANOPROTECT hex

CNTSNK-CONI-HSCO-NANOPROTECT-HEX-D10,4MM

Art.-no. 0694299104

EAN 4099618843938

Register now and access more than 125,000 products

Maximum comfort due to innovative cutting edge geometries

- Four cutting edges (instead of the conventional three cutting edges) distribute the forces over more edges and allow for smoother and more precise countersinking with less effort and a longer service life

- Patent-pending combination of straight and spiral cutting edges ensures fewer breakouts, better centring and chip removal (due to the straight cutting edges) as well as significantly less effort and a longer service life (due to the spiral cutting edges)

Maximum service life due to nanoProtect coating

- Significantly longer service life than conventional countersinks with coating

Maximum precision due to extremely unequal pitch (EU+)

- Optimal surface quality: precise, round, chatter-free countersinking

- Maximum smoothness

Maximum flexibility in use

- Can be used universally with almost all materials

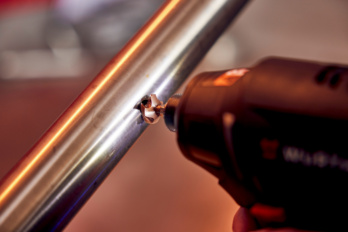

- Can be used in tangential impact drivers as well as conventionally in drill/drivers or with box column and pillar drills

Short version

- High stability and attractive price

1/4 inch hexagon bit shank, type E

- Secure hold and optimal power transmission in the drill chuck

- Extremely fast tool change in tangential impact drivers

Available exclusively from WÜRTH

Product packaging made from 100 % PCR (recycled plastic from household waste) and 100 % recyclable

- For use with 1/2 inch impact drivers, only use the adapter 0997148462. It is strongly advised against using any other adapter as this could cause countersink breakage.

- When used with a tangential impact driver, countersinking in accordance with DIN 74-1 to allow countersunk head screws to sit flush with the component is only possible with countersink diameters of 6.3 to 12.4 mm. Although larger countersink diameters are perfectly suitable for deburring the drill hole, they are not able to countersink deep enough for countersunk head screws to sit flush in accordance with DIN 7991 when used with a tangential impact driver. Conventional use with a drill/driver is recommended for this application!

- Cooling is strongly recommended for a much longer service life!

Datasheets(X)

- Ideal for use in tangential impact drivers

- Ideal for use in cordless drivers as well as on hand-held, box column and pillar drills

- For universal use in almost all materials, such as stainless steel (e.g. V2A, V4A), heat-resistant steels and titanium. Also for general applications in conventional steel up to 1,400 N/mm², as well as in cast iron, aluminium, plastic, non-ferrous metals, compact and hard wood, and soft and light wood.

- For the best countersinking result, low speeds are recommended - see cutting values overview in the product info

- Particularly when used in tangential impact drivers, a low speed in first gear is essential to avoid the impact function and the resulting chatter marks

| |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Special alloy, Hard and tough material, Non-ferrous metal, Plastic, Aluminium |

Quality | ZEBRA-Premium |

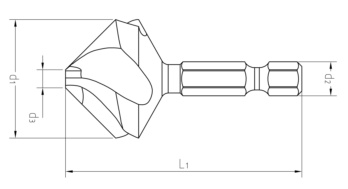

Spot-facer diameter (d1) | 10.4 mm |

Shank diameter (d2) | 1/4 in |

Tip diameter (d3) | 2.5 mm |

Length (l1) | 38 mm |

Number of cutting edges (Z) | 4 PCS |

Cutting material | HSCo |

Countersink angle | 90 Degree |

Surface | nanoProtect |

Shank style | Hexagon bit holder, shape E, DIN3126 |

Service life (points system) | 4 of 4 points |

Countersinking speed (point system) | 4 of 4 points |

Countersinking quality (point system) | 4 of 4 points |

Versatility (points system) | 4 of 4 points |

Countersinking behaviour (point system) | 4 of 4 points |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, White cast iron, Stainless steels, sulphurated, Stainless steels, austenitic, Stainless steels, martensitic, Titanium, Titanium alloys, Special alloys, Hardox, Spring steels, Aluminium alloys, Aluminium wrought alloys, Aluminium casting alloys (>10% silicon), Aluminium casting alloys (<10% silicon), Magnesium alloys, Copper, Brass, short-chipping, Brass, long-chipping, Bronze, short-chipping, Bronze, long-chipping, Plastics, thermoset, Plastics, thermoplastic, Plastics, aramide-fibre reinforced, Plastics, glass/carbon-fibre-reinforced |

| Assignment of countersink to screw standards | ||

| Countersink nominal diameter d1 | for countersunk head screws | for countersunk head screws |

| DIN EN ISO 10642 (formerly DIN 7991) | DIN EN ISO 2009, 2010, 7046, 7047 (formerly DIN 963, 964, 965, 966) | |

| 6.3 mm | M3 | M3 |

| 8.3 mm | M4 | - |

| 10.4 mm | M5 | M4, M5 |

| 12.4 mm | M6 | M6 |

| 16.5 mm | M8 | M8 |

| 20.5 mm | - | M10 |

| 25.0 mm | M10, M12 | M12 |

| 31.0 mm | M16 | - |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!